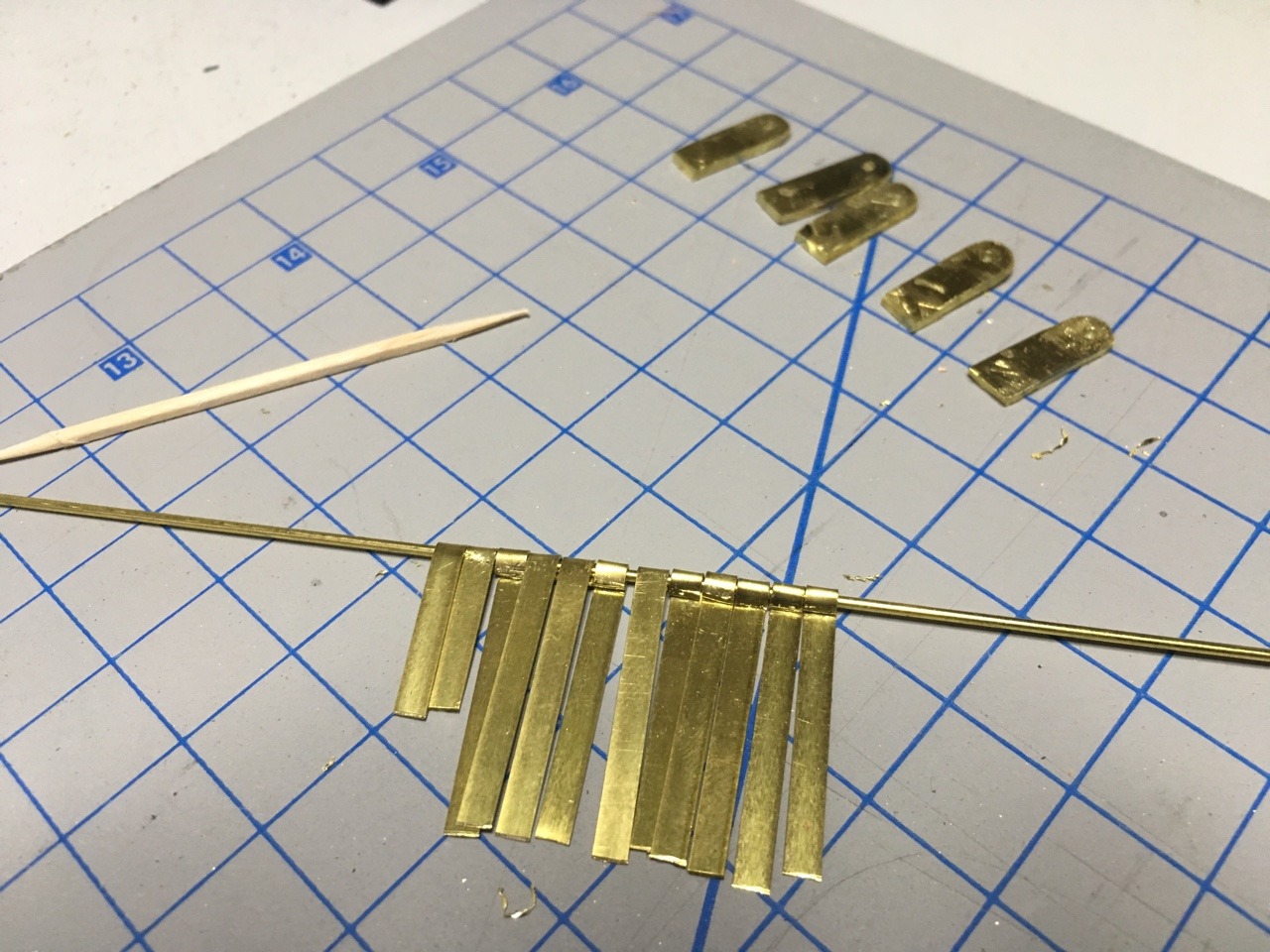

With the Durango & Jasper mine spur mostly done, it is time to build some hoppers to move gold ore to the stamp mill. Keeping with the theme, these hoppers are short. However, I’m kind of a sucker for 4 axle cars, so I’m making these as short as possible given that I want regular trucks. The cars will be 9 inches long and about 5 inches wide (4.5 for the platform and then the door supports extend it out another .25 inches on each side).

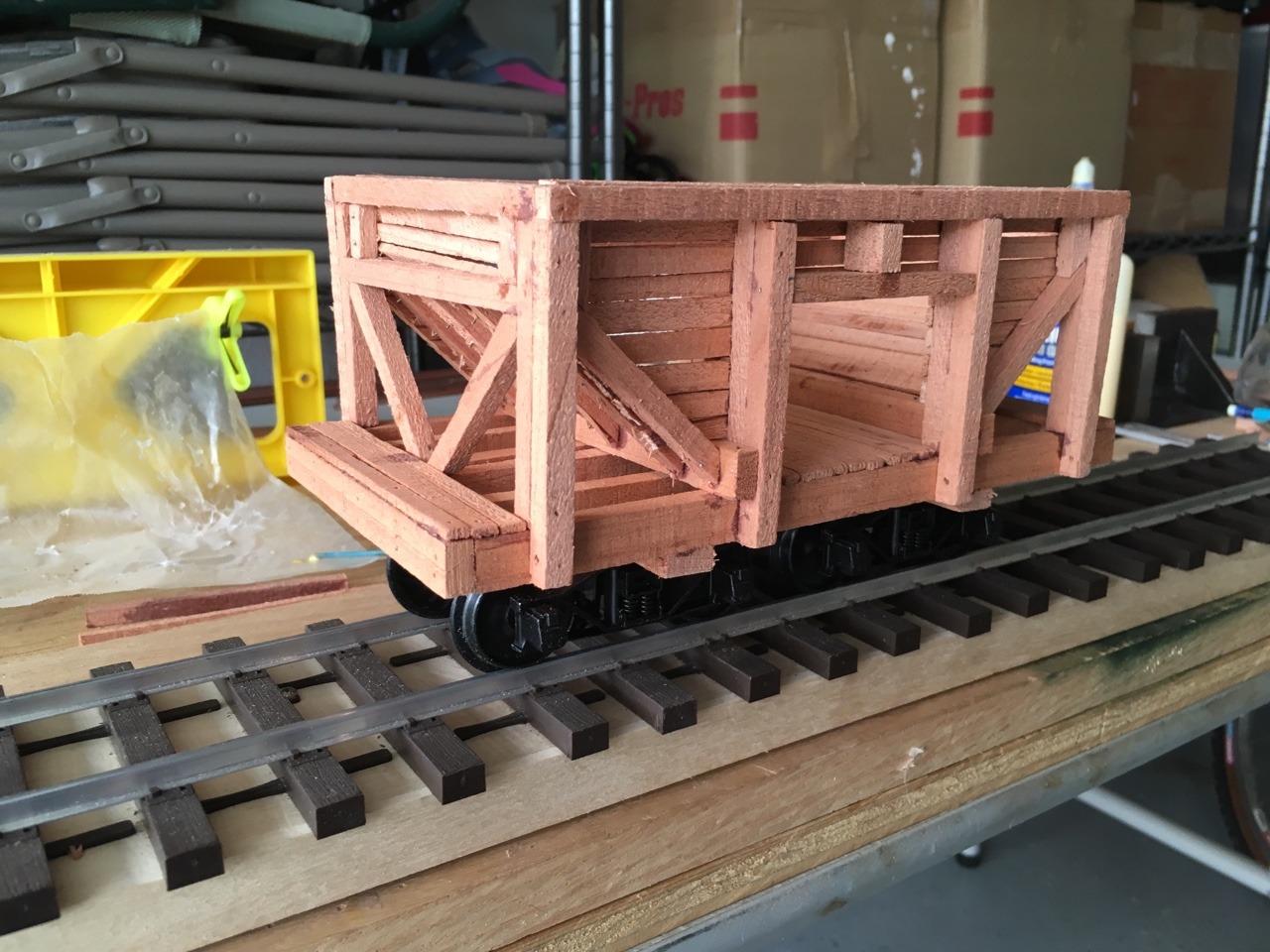

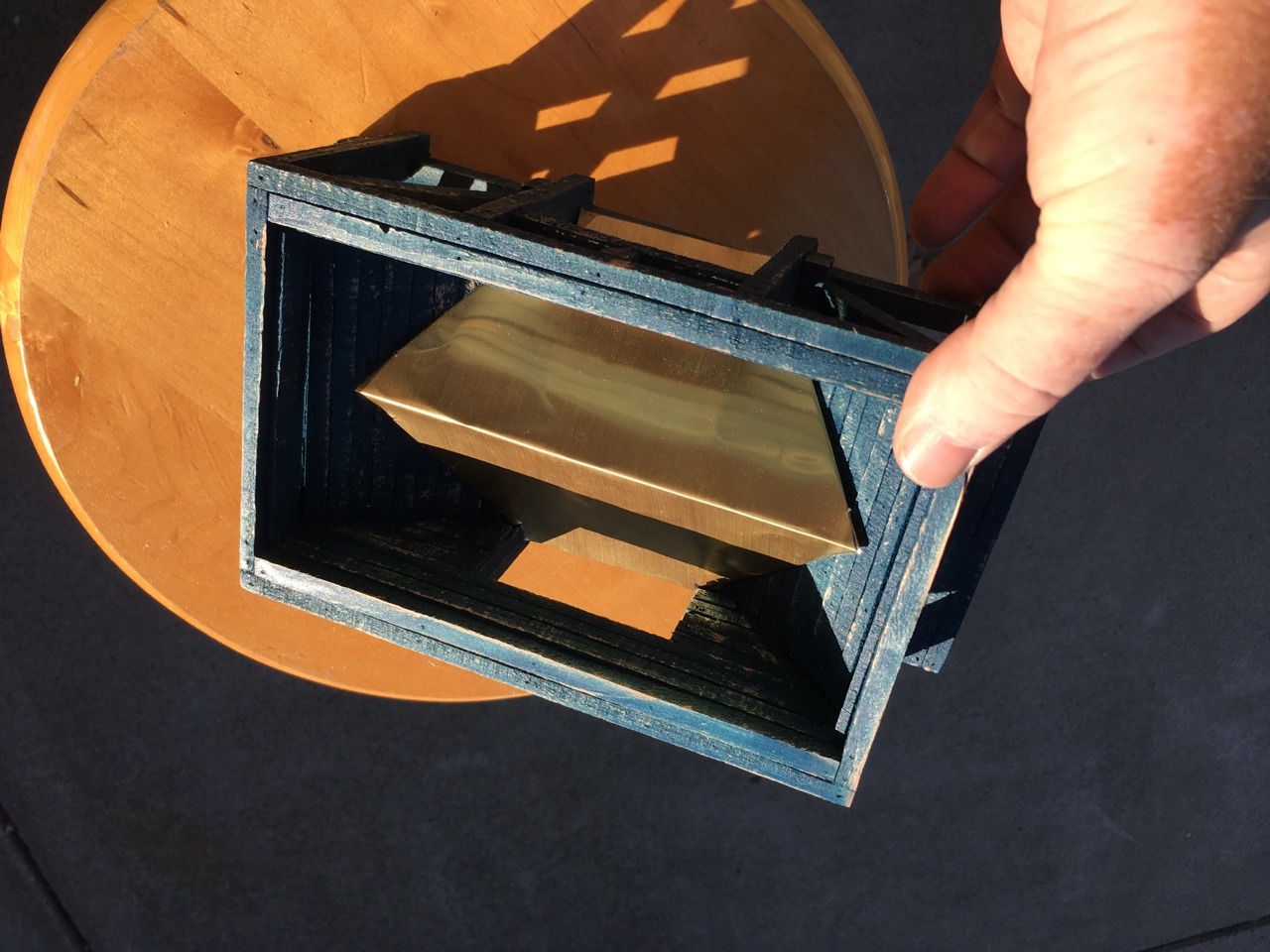

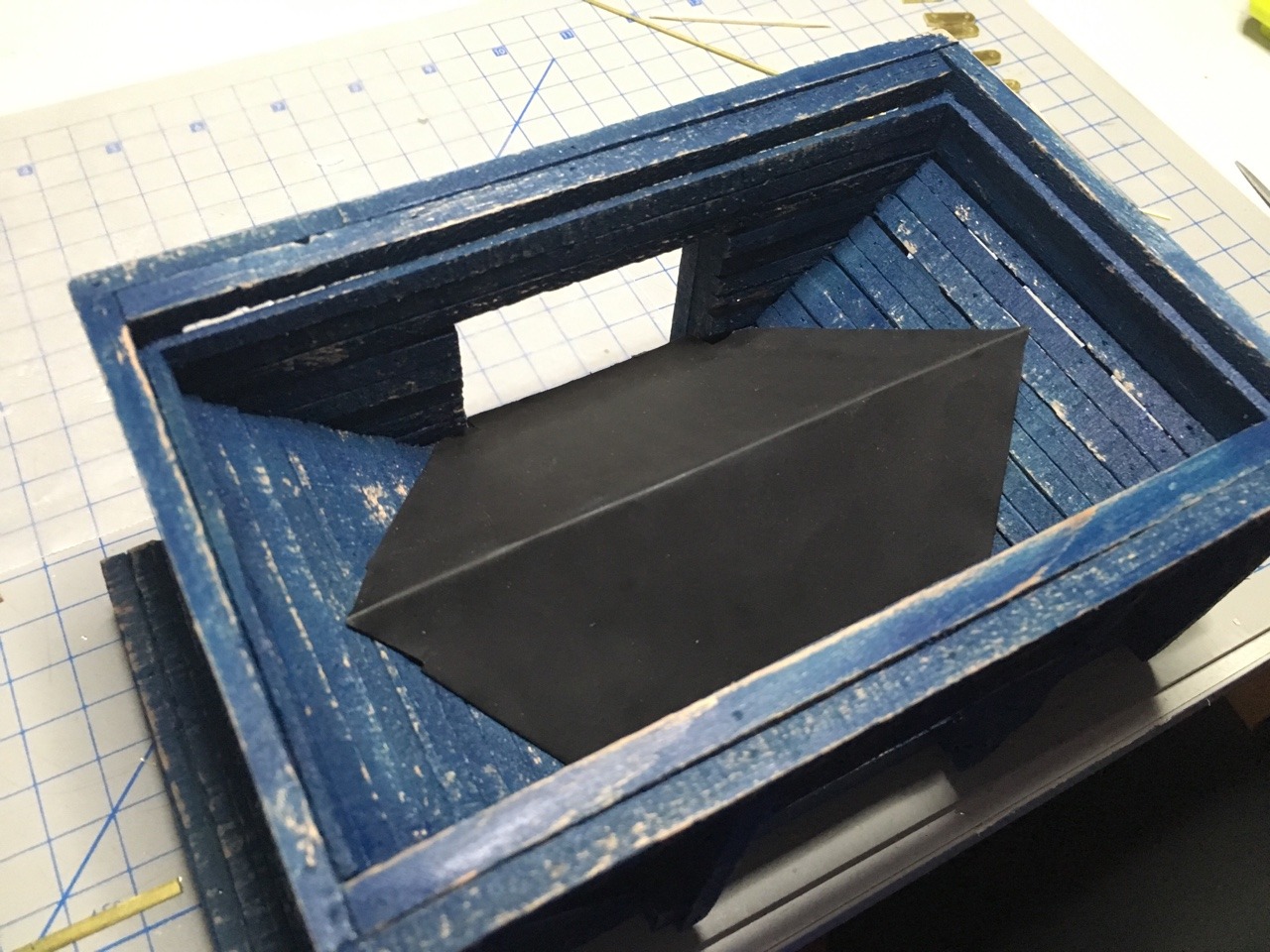

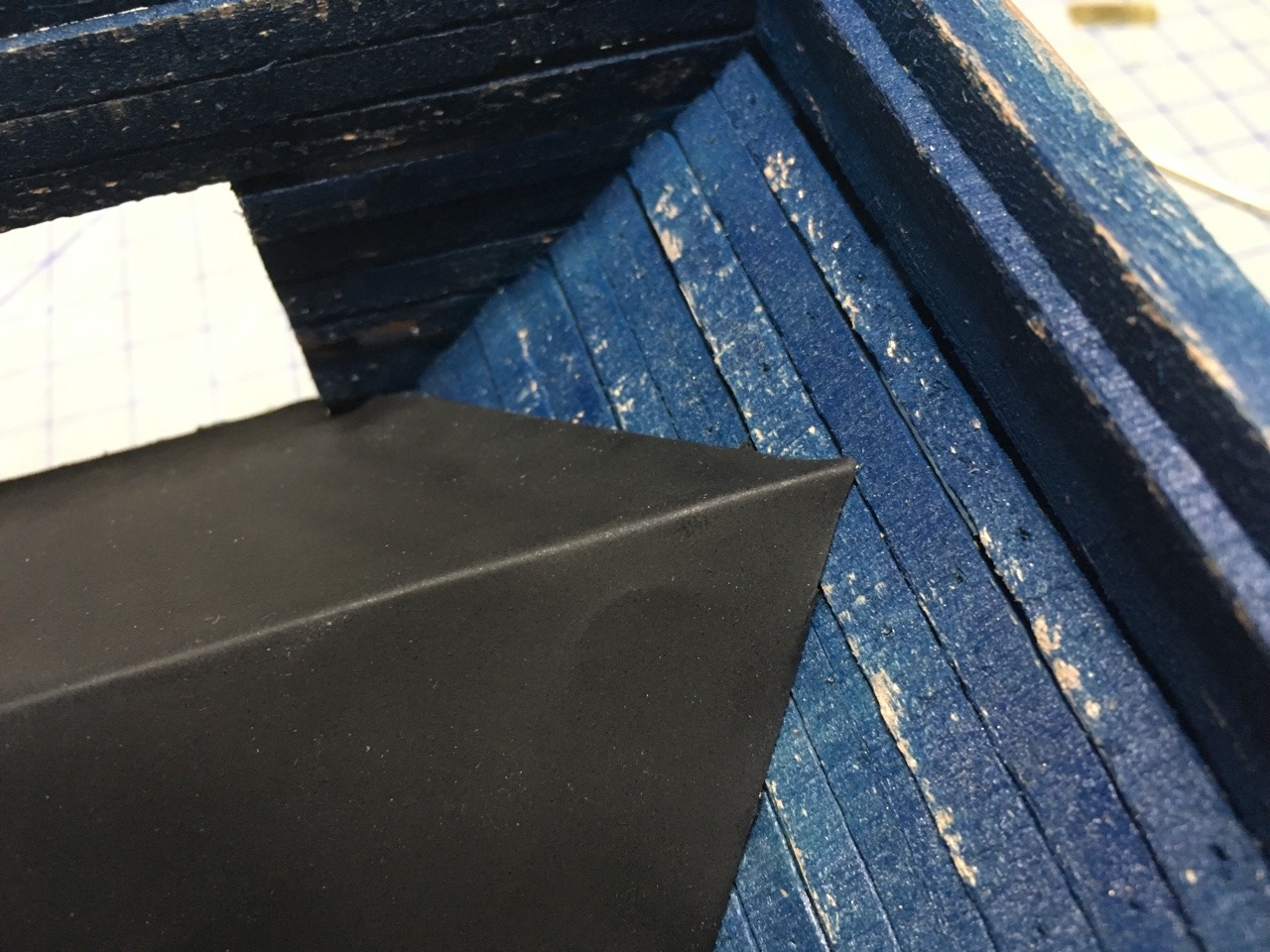

Here’s the inspiration for this build. It is a wooden car with doors on each side for getting the ore out at the stamp mill:

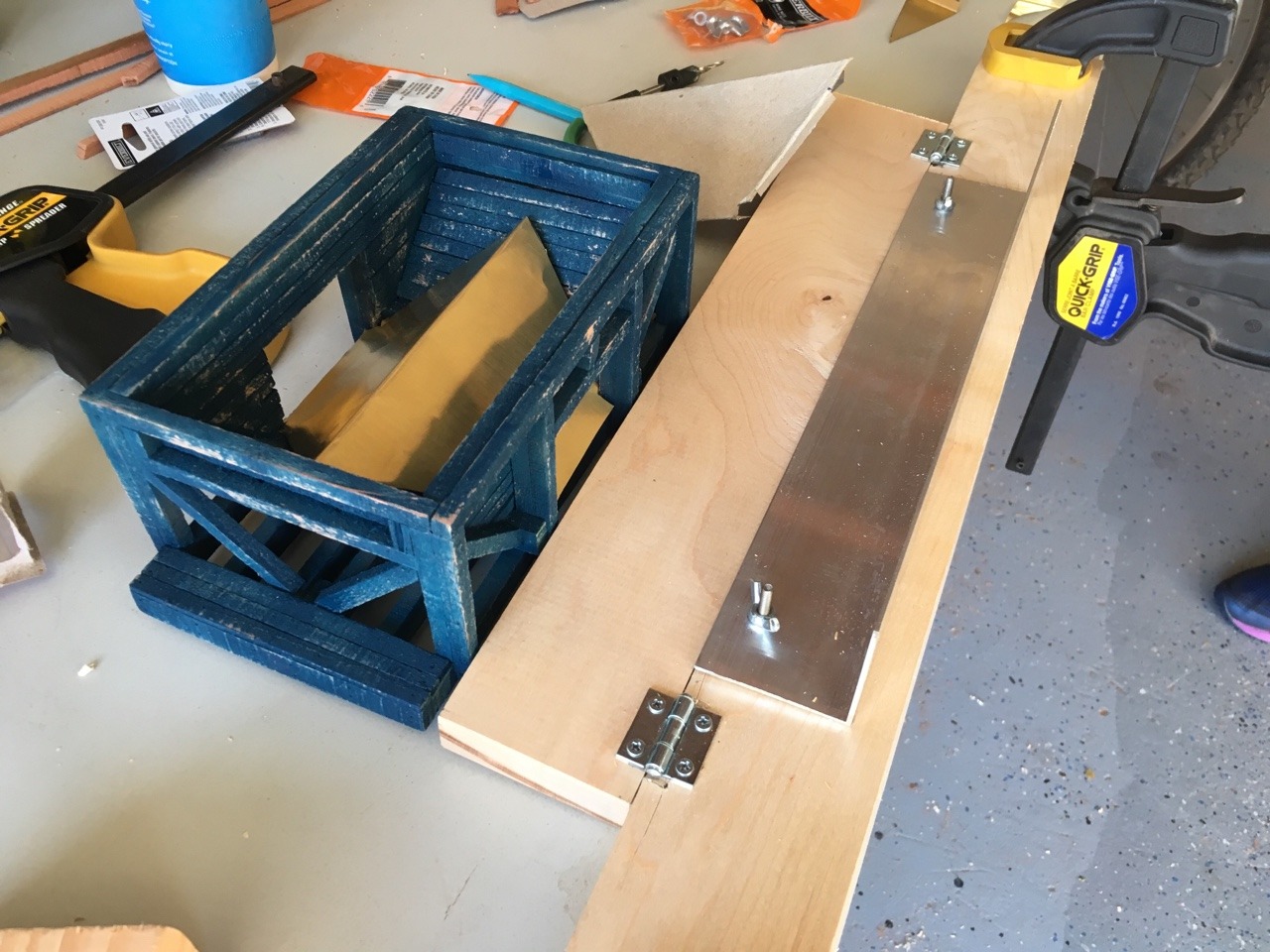

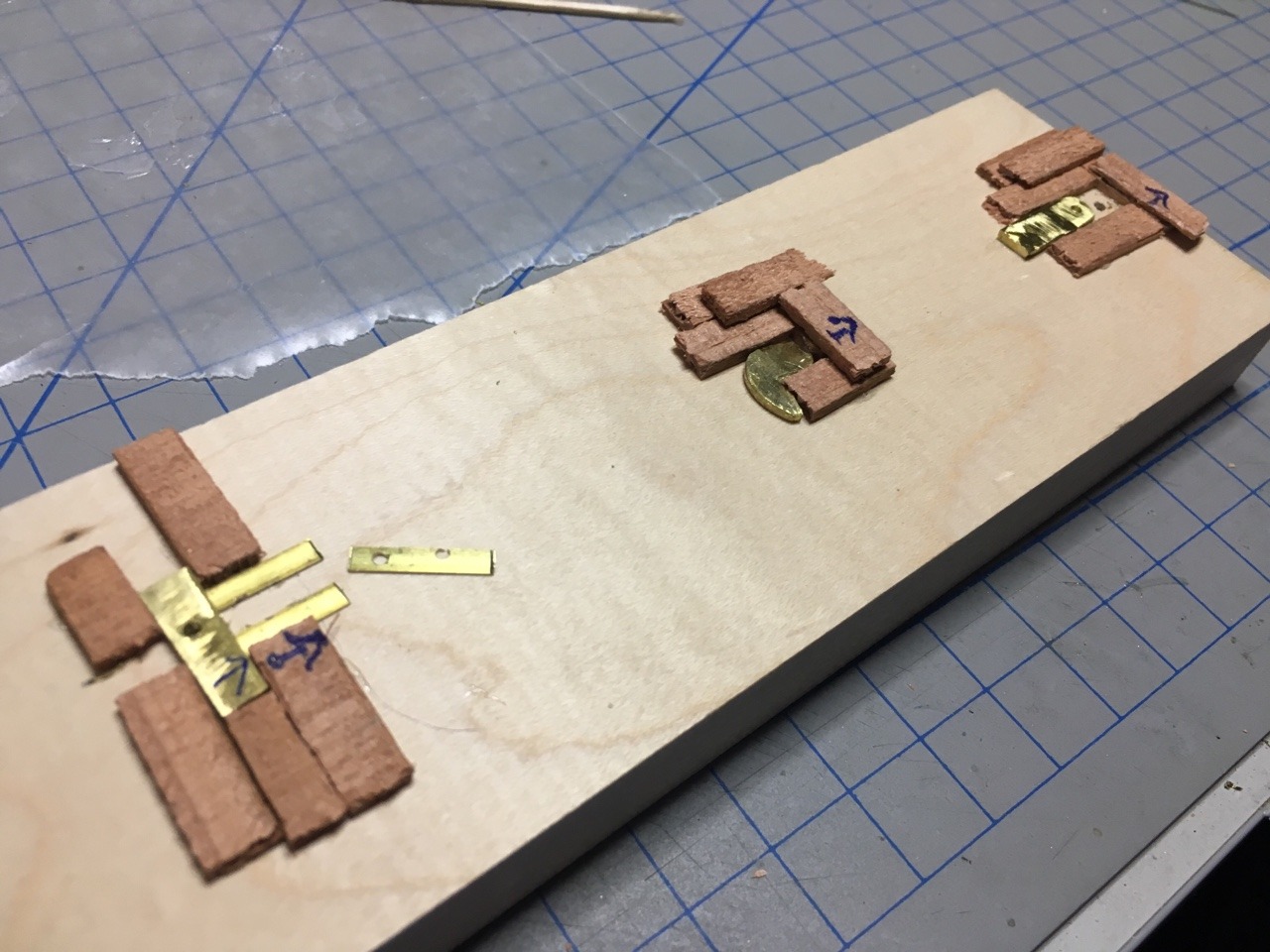

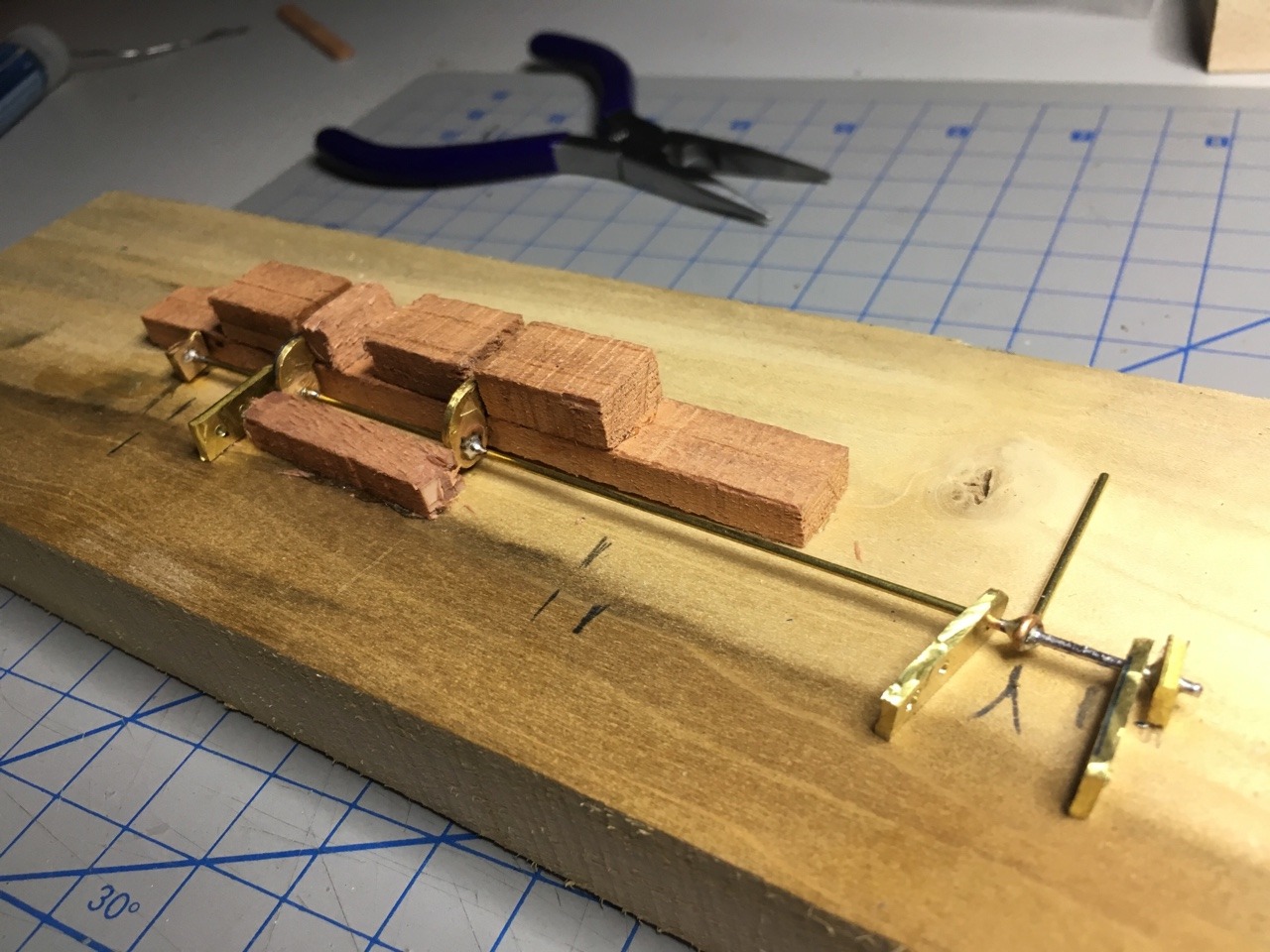

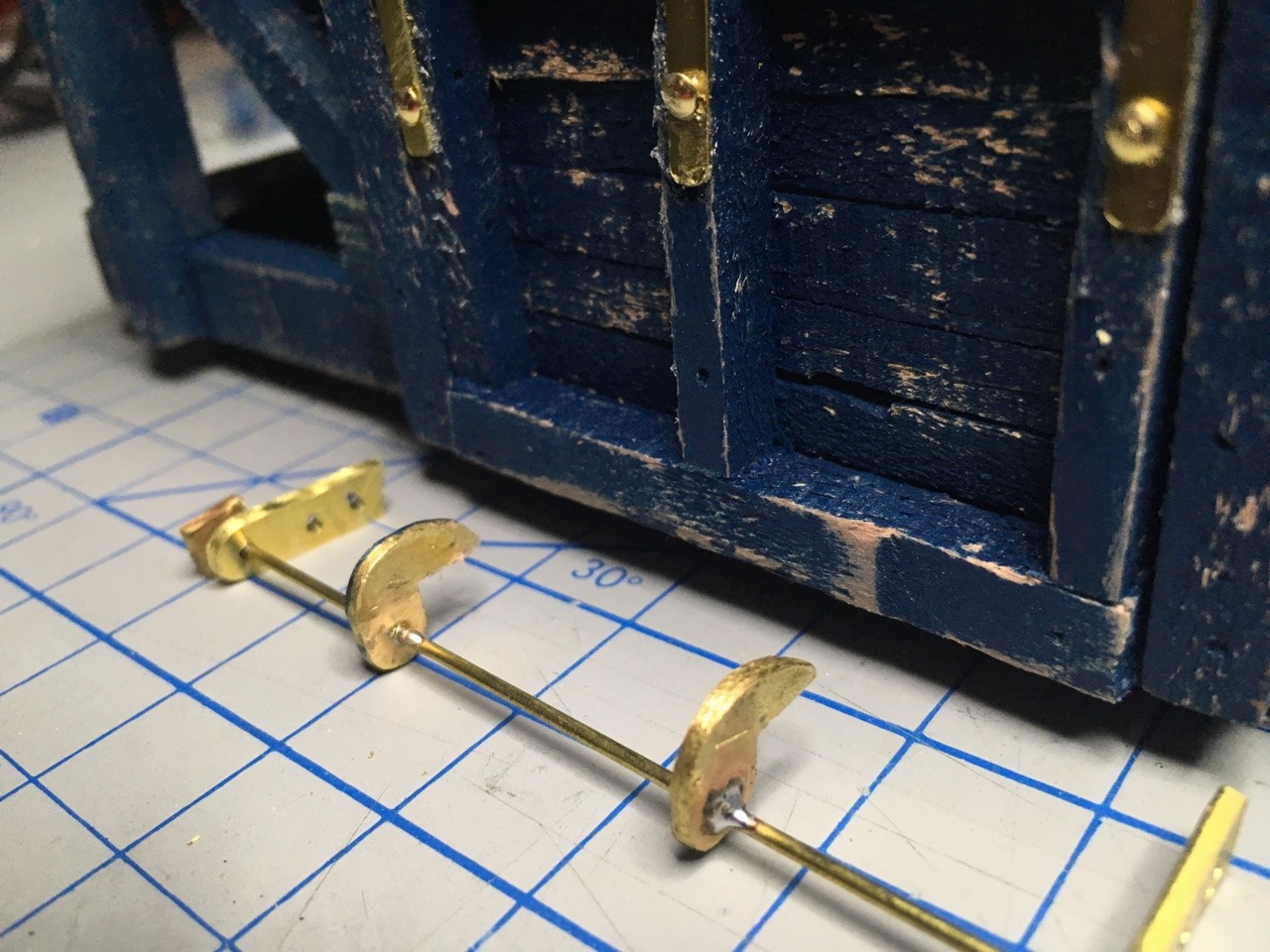

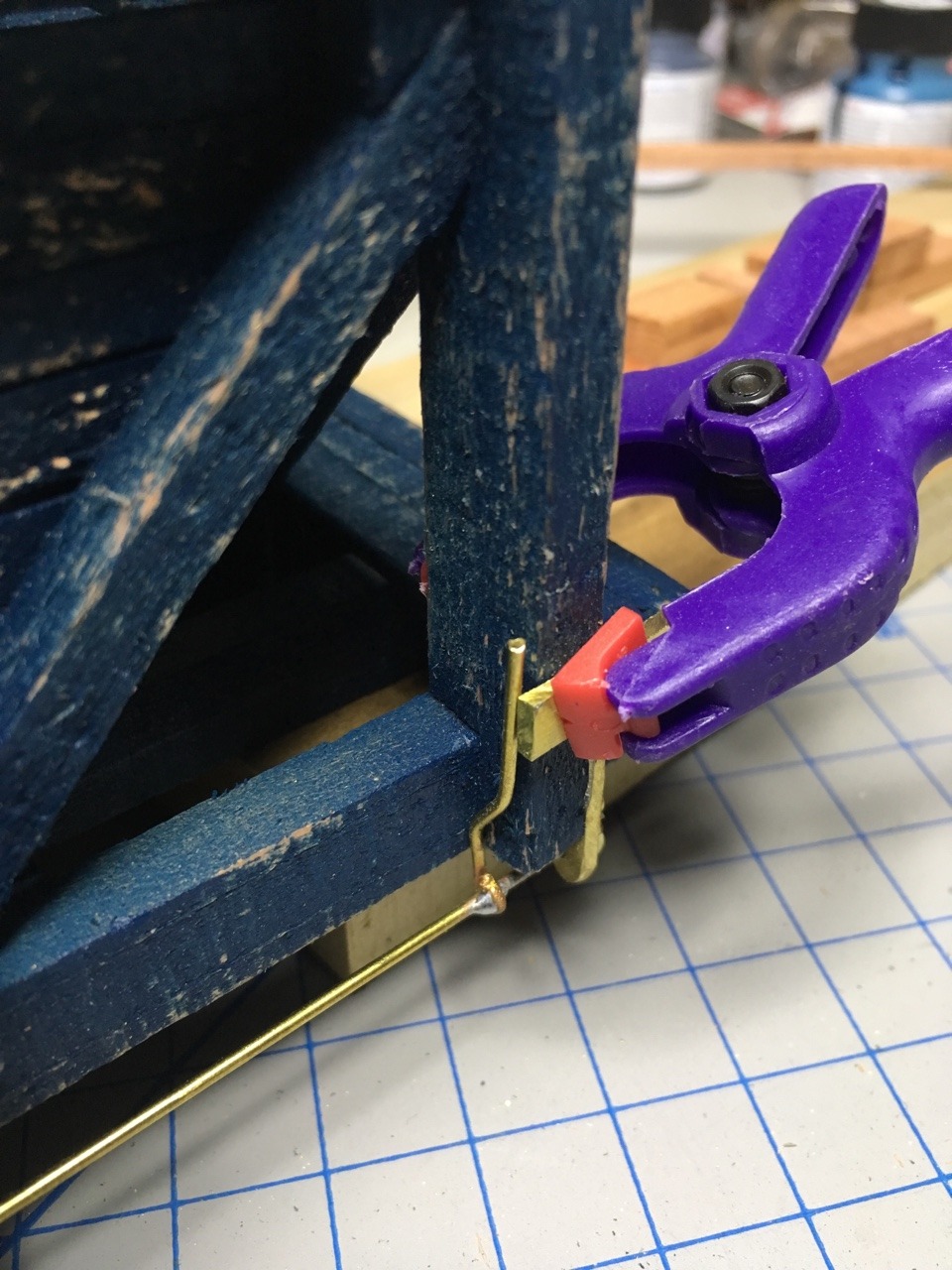

Here’s the platform just being started:

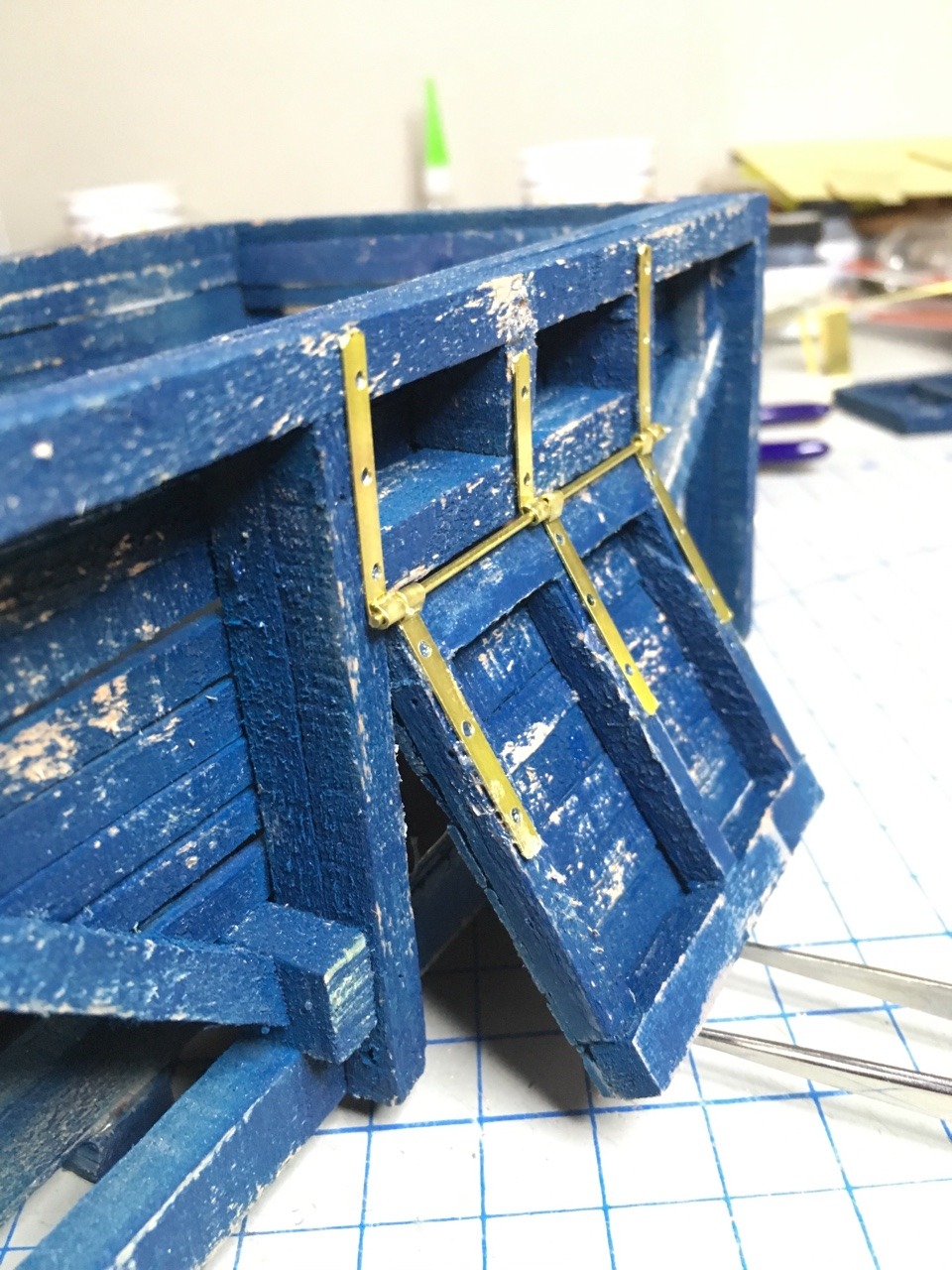

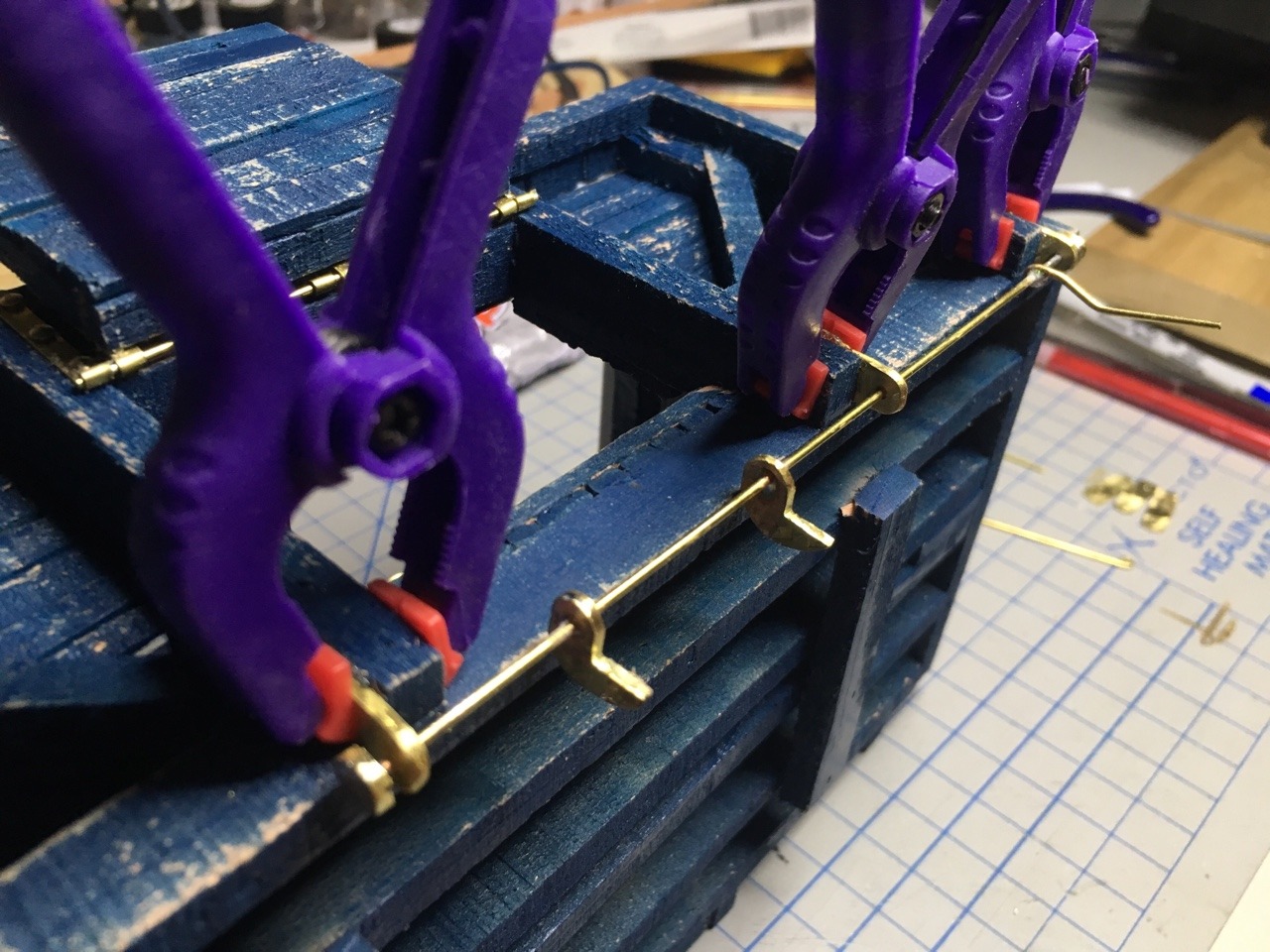

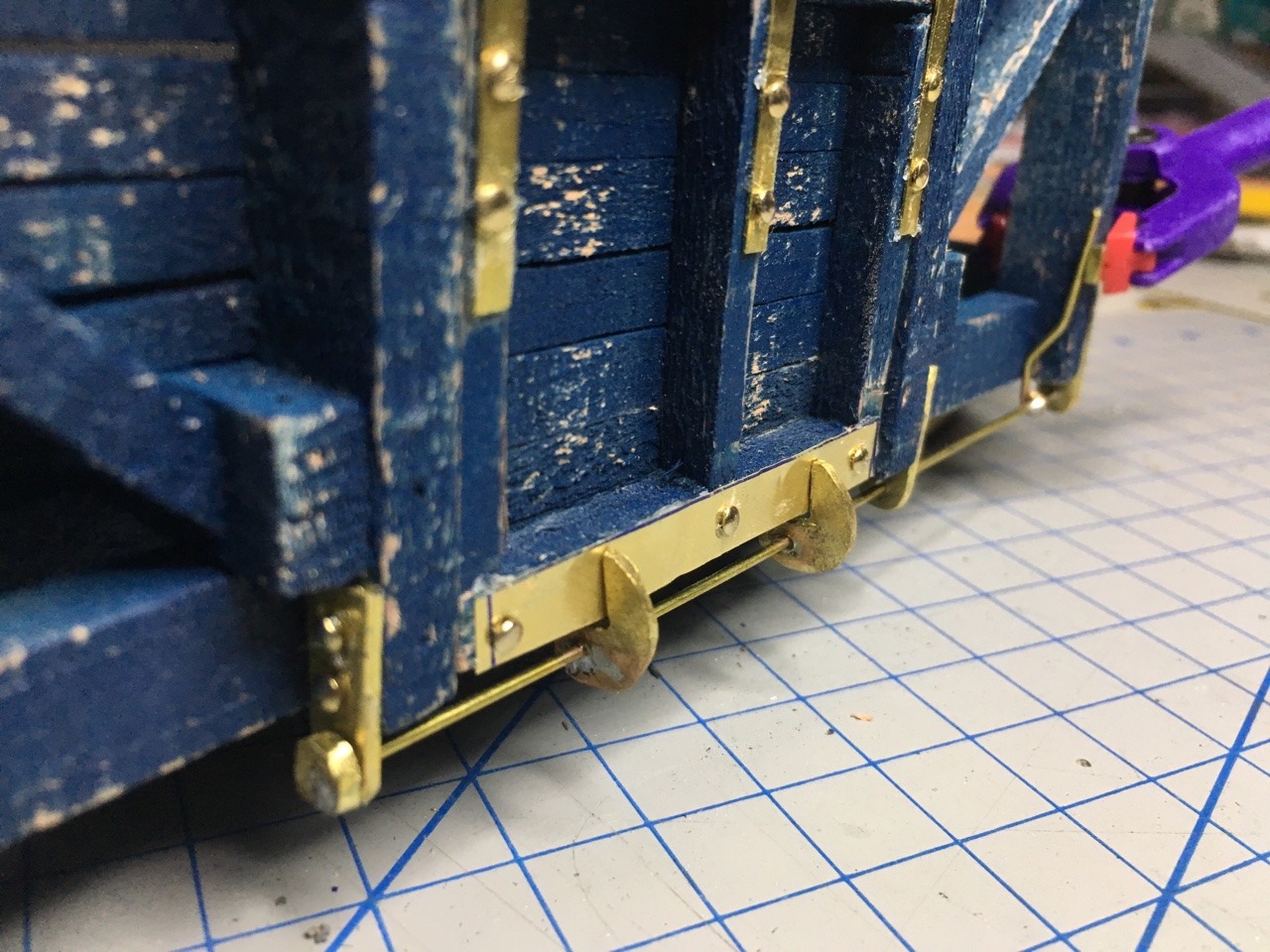

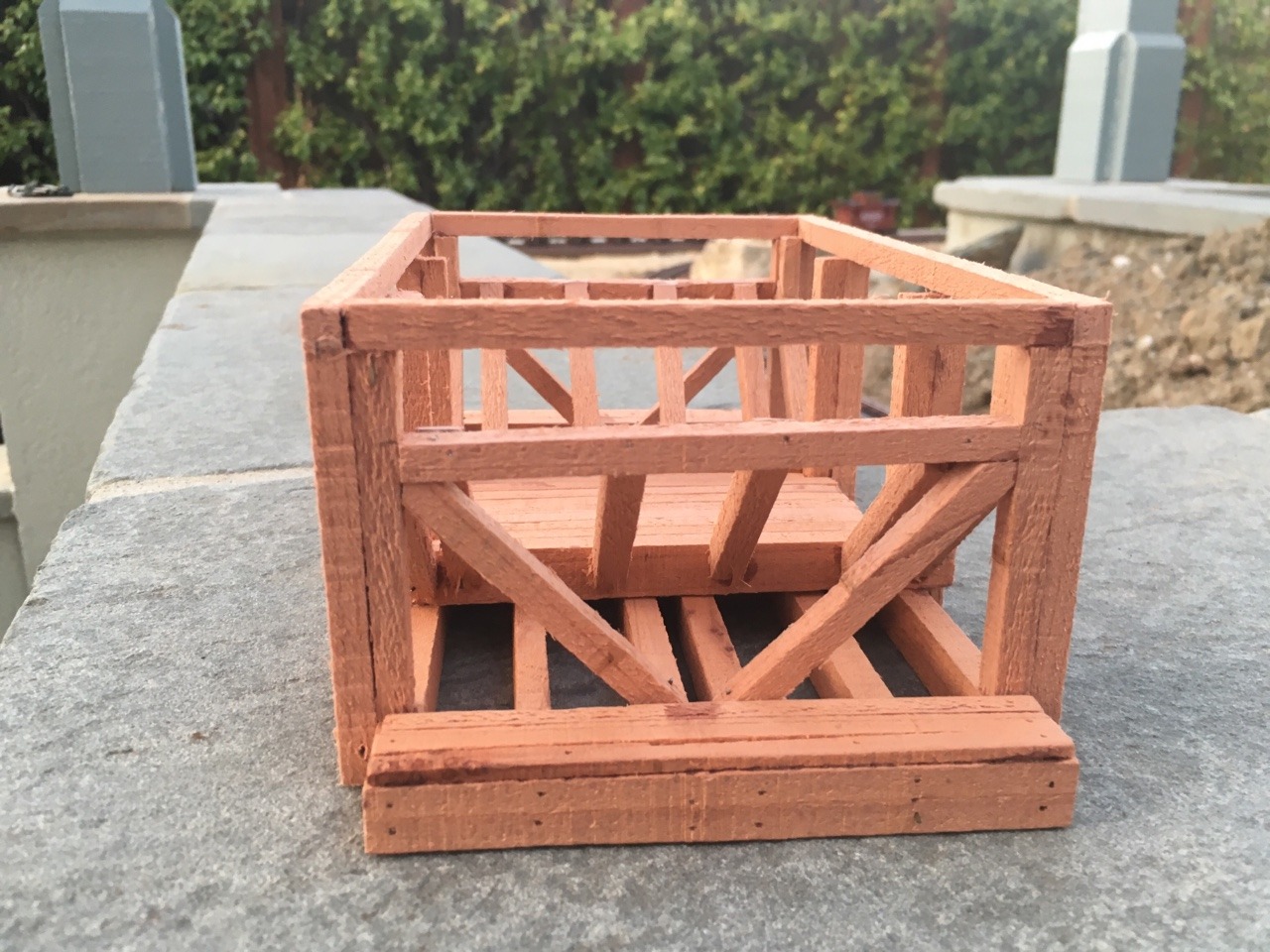

I’ve started framing the hopper as I puzzle out the design. After I get one done, I’ll build another three (for now). Like my wooden water car, this is built from scrap redwood leftover from the track bed.

Here is the frame car sitting near the mine:

Should be a tight fit, which was the goal.

As always, suggestions are highly appreciated.

Cheers!