I guess it depends on how elaborate your fabricators want to be. But a sliding deadbolt would work.

I guess it depends on how elaborate your fabricators want to be. But a sliding deadbolt would work.

Jim Rowson said:

This car turned out a bit rough around the edges but …

Eh, it ain’t a Pullman, so that’s okay.

That is some mighty fancy hardware! Nice work (https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-cool.gif)

I’d go with #3 to hold your lever. Some type of swinging ‘dog’. Could be beveled so to lock you just push the lever back and the dog pushes out of the way, then swings back by gravity to lock the lever in place. To open the operator would swing the dog away from the lever.

I don’t know how prototypical that is, but it’s how I would do it if I was a car builder and already have the hardware you have designed.

Jon Radder said: Some type of swinging ‘dog’.

Hey, there’s a layout structure, the Swinging Dog Bar and Grill; or, Swinging Dog Pub.

SDB&G’s mascot could be beagle, Jack Russel, chihuahua, something like that, sitting on top of a tire swing.

Also possible, a Dachshund on a wooden plank playground swing.

Jim, Thinking about how a 1:1 scale car would work there would be a lot of pressure against that door and the corresponding release handle. The operator would want to be able to release it and get out of the way quickly as I imagine it would swing open with force just like in your video. With that in mind I’m picturing the operator using a hammer to pop open a release tab of some sort. I think if you made something along those lines it would look more than plausible. Look forward to seeing what you come up with.

Steve

This functional build is turning out to be really something. Is worth it just for the homebuilt bender.

I would have gone with a somewhat greyer flavor of blue.

I’d go with a collar that can slide up the post and then down over the handle. Could be made of wire to keep the weight down, but be strong enough to keep the handle snug. As a collar on the post it’s always there, put you knee on the handle and slide the collar down.

Here’s how the D&RGW did it on their drop-bottom gondolas. You can see the plate and pin holding the lever upright. (Orange Empire Museum, 2012.)

Thanks, all, for the ideas and encouragement! Must mull things over and do a few sketches/trials. I’d sure like it to be as simple as possible (like the prototype photo that Pete provided), but do want it to hold the door pretty firmly closed even though there’s a lot more “spring” to these rods than would be happening at 1:1.

I have to say, bumbling around to figure out how to make the hinges and closing mechanism has been a blast so far…

But, I’m itching to get this thing on the track

Jim Rowson said:

I have to say, bumbling around to figure out how to make the hinges and closing mechanism has been a blast so far…

But, I’m itching to get this thing on the track

That’s part of what makes this a well rounded hobby - conceiving, designing, making, using.

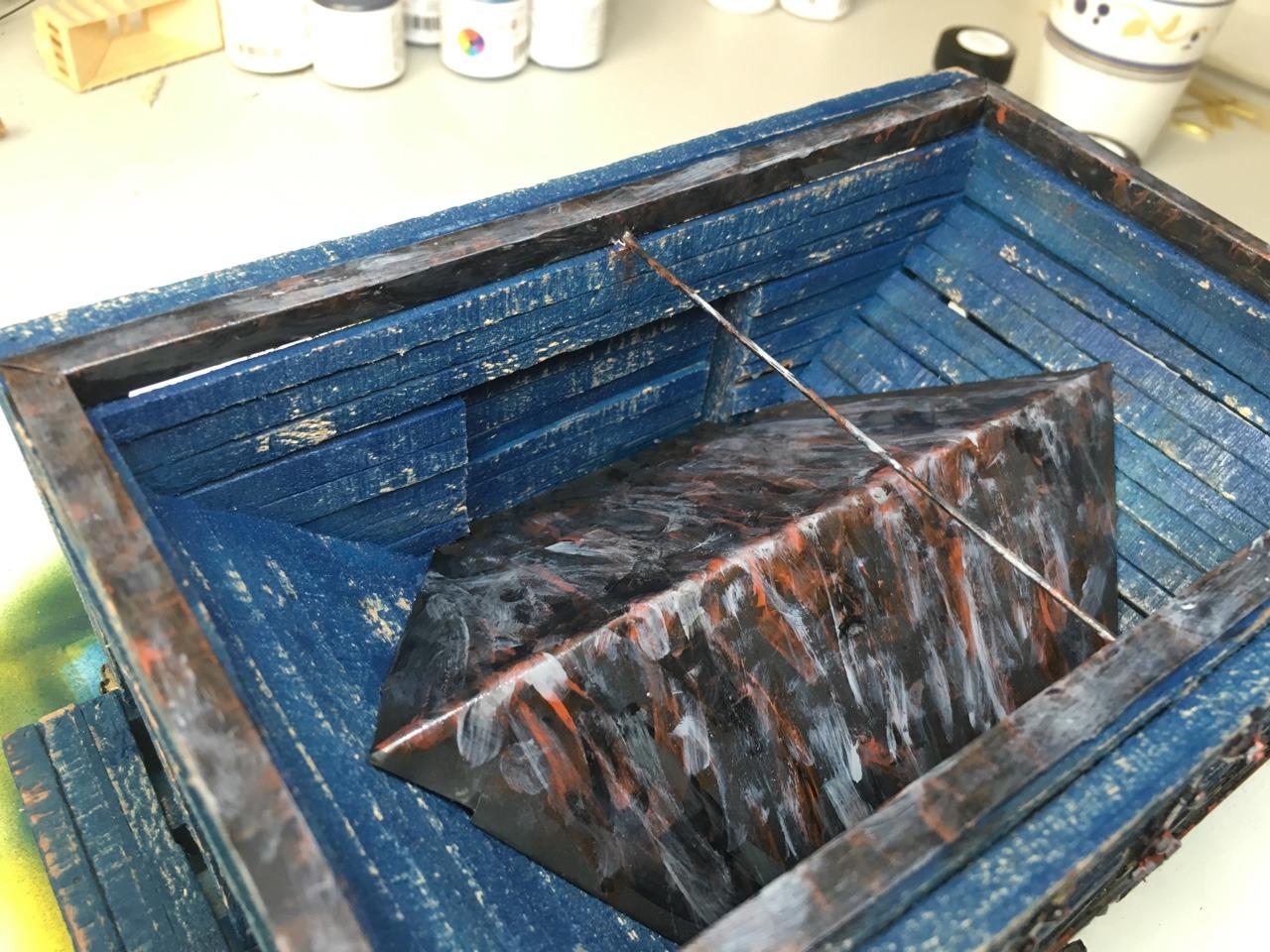

While I mull over options for holding the doors closed, I started to paint/weather the hopper.

I’m a little unhappy with the internal, metal sheeting. My goal was to streak it, to give the impression that the rust and wear/grime is heavily influenced by the ore being dumped in and sliding out. Not so sure I accomplished that.

It’s just paint so not hard to modify. Suggestions?

Jim Rowson said:

While I mull over options for holding the doors closed, I started to paint/weather the hopper.

I’m a little unhappy with the internal, metal sheeting. My goal was to streak it, to give the impression that the rust and wear/grime is heavily influenced by the ore being dumped in and sliding out. Not so sure I accomplished that.

It’s just paint so not hard to modify. Suggestions?

It looks excellent! as for the internal, I would recommend an India ink/alcholol mix. go a little heavier on the ink in a brown color, then apply a few times. it runs and gives a nice rust look after a few coats.

I’m a little unhappy with the internal, metal sheeting. My goal was to streak it, to give the impression that the rust and wear/grime is heavily influenced by the ore being dumped in and sliding out. Not so sure I accomplished that

For weathering, I like acrylic paints. Lots of dilute grey/black/charcoal and other similar colors from your local craft store. Let them drip down the side of the metal and keep adding more dilute (even more dilute) washes.

Ore being dumped in would pock-mark the metal surface. It looks too new - needs some craters and other blemishes, as the outside screams "old’!

Some rock dust if you can get any would also help to treat the inside sheet and walls. I was going to suggest charcoal or coal dust but then remembered these are ore hoppers, not coal hoppers.

One thing about weathering; it helps to be deliberately random if you can get what I mean. Last week at work I needed to create a rusty steel look on painted aluminum. I use Modern Masters Iron Paint and Oxidizer. The paint is a straightforward application, but the oxidizer takes some doing to get a natural rusty look. I sprayed with an old Windex bottle from far, then very close creating deliberate runs; then put some on a foam brush and flung it off from 3 feet away; then threw the wet brush at the surface bouncing it off leaving marks that there was no way I could have done by hand!

If you want that paint to crinkle up try a very quick and light wash with acetone. Try that on a test piece first to see what it will do - too much will take everything off.

To bad Mac MacCella’s page is gone. He was the master - try the Wayback machine for “make them old and dirty” but be careful of search results for that phrase (https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-surprised.gif)

Jim,

You’re making good progress. Weathering the interior should look well used with worn shinny steal streaked with some rust in the less worn area. Check out the blade of my dozer. I removed the paint to show natural ware leaving paint where it wouldn’t ware as much. You used copper so try painting it silver and apply light streaks of rust in the direction the gravel would slide. I use Rust-Oleum Rusty Metal Primer 8 oz can, it has good rusty color and can even be thinned to use as a wash as well.

Nice build! I haven’t weathered brass sheet yet, but there might be a first time. Some of my thoughts are to clean the brass good. Then scuff it with steel wool so

the primer will stick good. Paint a coat of grey zinc oxide ( This helps regular paint stock to brass or aluminum.) Then a coat of red/brown primer.i When that dries.

use a piece of stiff wire to then see if you can scratch through the brown primer in a down

ward fashion. Then a black alcohol wash over everything. Play around with scrap pieces.

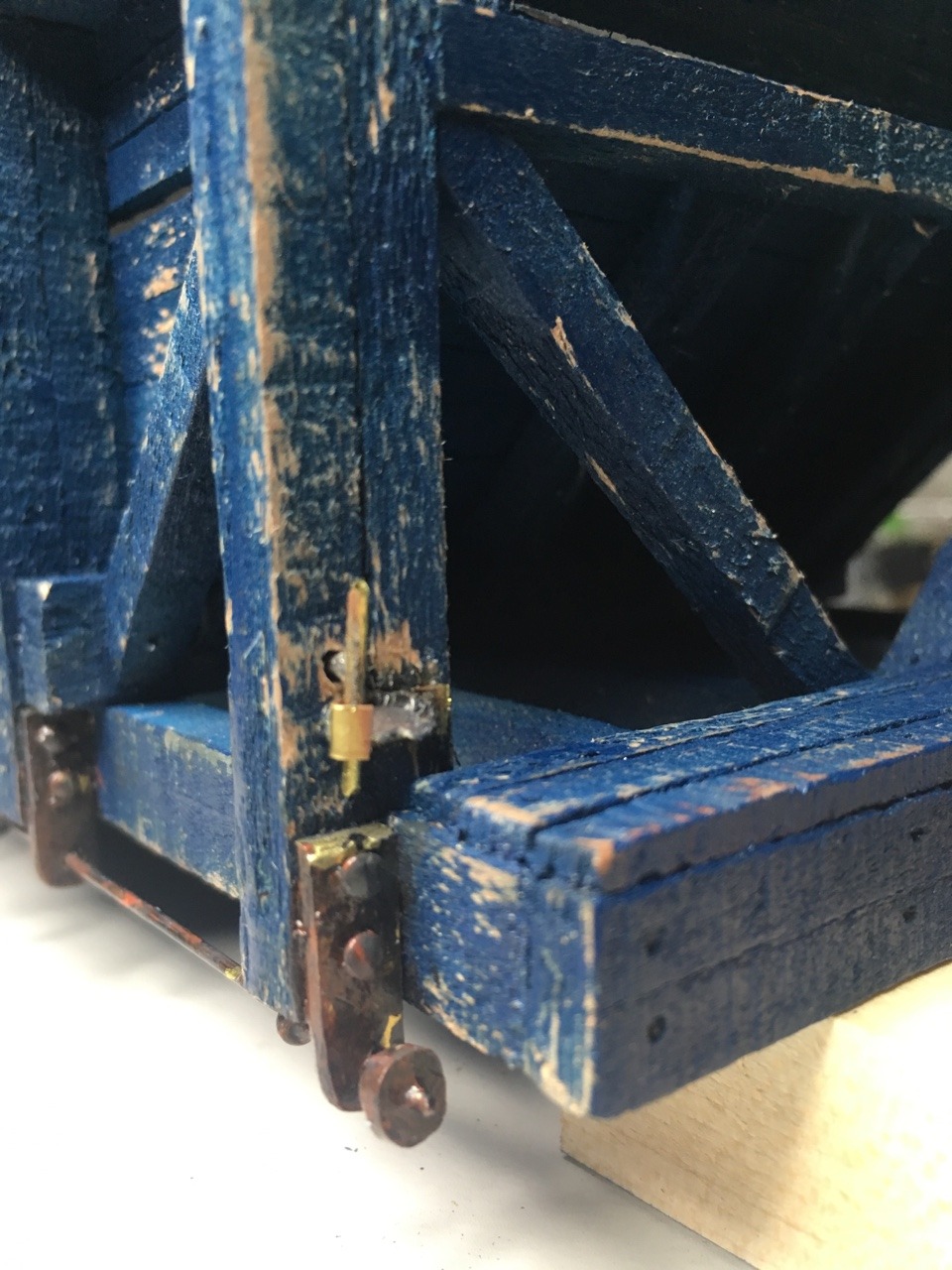

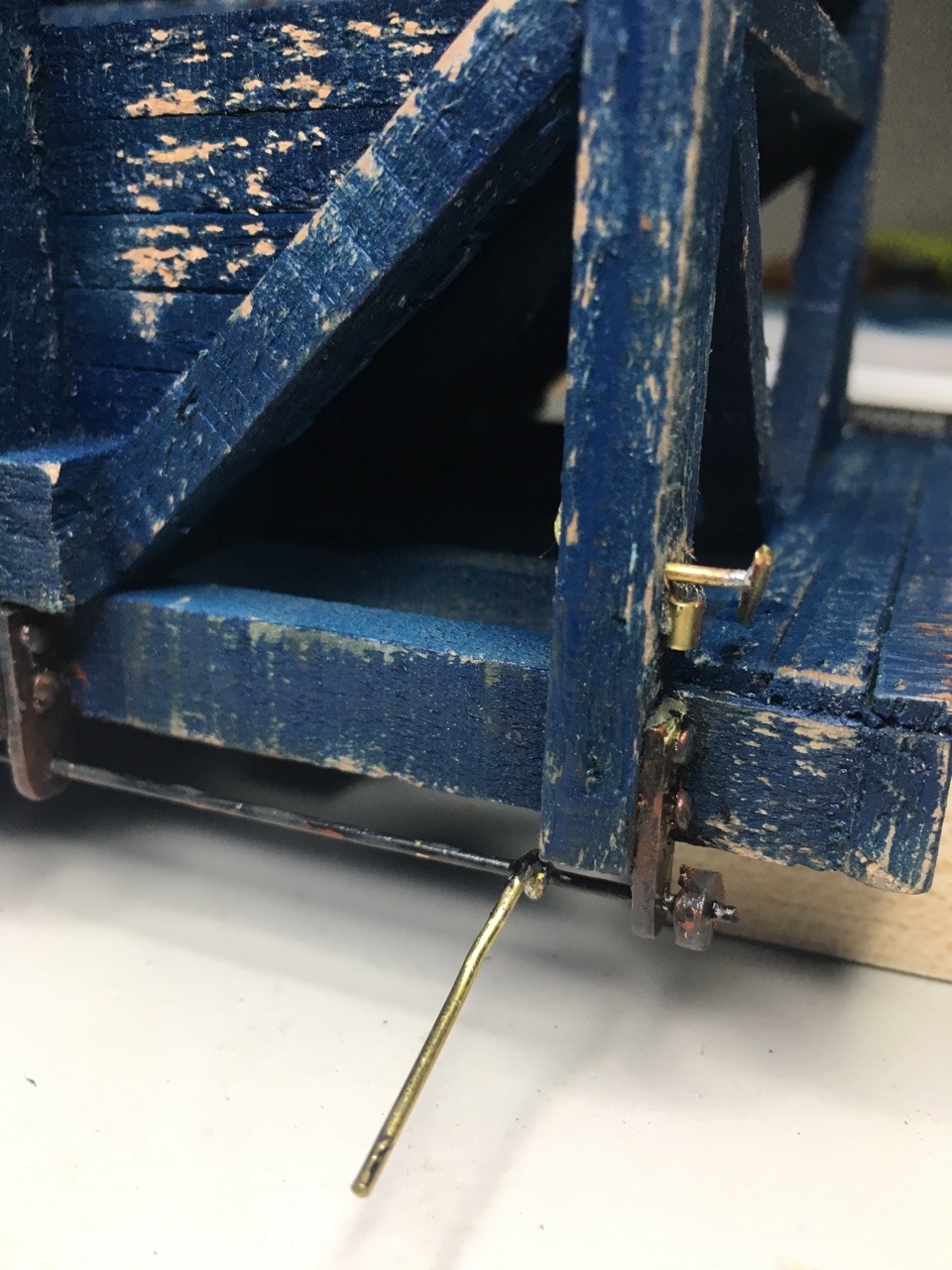

Thanks for all the suggestions regarding the door closure mechanism. My fabricators are a bit weak, and after thinking about it for longer than I should have, I went with a reasonably simple scheme. I’m going to show it in 4 steps to show the behavior (it was too hard to make a video as I needed 4 hands or so).

First, there’s a T shape soldered perpendicular to a rod that goes through the wood support, it then clips into a shaped piece of brass to keep it from moving:

At the other end of the rod going through the wooden support is an L shape (or at least as close as I could get) that also helps keep the rod from shifting toward the wood support.

To open this, you turn the T shape (top toward the camera):

Then you pull the T shape toward the front of the car, allowing the lever to escape, opening the door to the car:

Of course, to close it you reverse these steps.

Any reactions? This seem reasonable at all?

A couple of thoughts on my side:

I am probably overthinking this, but I find it fun to attempt to solve these puzzles.

Thanks again for all the ideas.

Love it!

You ain’t {pa dutch} (are not) overthinking!

Simple and sweet. Nice work Jim(https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-cool.gif)

i like the idea, and how it is executed. well done.