Well are we cleaning out the smokebox or the firebox (after all thats is where the ashpan is). Now I would have never thought of cleaning out the smoke box. But since smoke does carry with it ash and embers it would require it to be cleaned as well. I will have to admit ignorance as well there also. I know they had to clean the firebox. You learn something every day. Now I do know that at the base of many stacks there is a little chute for emptying the stack. I always figured the smokebox door was for maintenance but makes sense for cleaning.

See this is why I like diesels, none of this smokebox ashpit stuff to learn, fuel in smoke out the stack, pull freight. Simple , like my mind.

Ok enuff snarkyness, Jon , I keep looking at my Beer and BBQ thinking this thing is goint to be huge , but when I place a boxcar beside it, it looks small. Looks like you came up with a good revised plan that is still the same , I like the idea of being able to back it out the back too, seems like I seen one on a layout with a back door, just incase a longer loco needs work , it can go in with part sticking out the back side.

OK Grasshoppers, pay attention. The smoke box does fill partially up with ash and cinders. During normal running, the cinders and ash gets sucked thru the boiler tubes and the heaver particles, mostly the cinders, are designed to get left behind in the firebox, and not ejected out the stack to start fires in the woods along the right of way. The draft pattern of the draw on the fire, thru the tubes, allows the cinders to build up into a low velocity area along the bottom corners of the smoke box, and it creates it’s own draft area, custom tailored to the needs of the smoke box. An ultra self customized wind(draft) tunnel. The engine actually drafts better with this collection of cinders directing the air flow, then when the box is empty.

There is the smoke box on 315, after opening the door, and before cleaning it out.

If it runs better with this buildup, then why would you want to clean it out. Well generally you don’t, But if it builds up to deep, it can block the bottom rows of the boiler tubes, and then they will clog. And also if you get a clogged tube, there is no draft thru that tube to blow away the build up in front of it in the smoke box, and the cinders build up and can start to clog the adjacent tubes. Clogged tubes mean less boiler heat, = less steam, =less draft, =colder fire, =etc, etc. A couple of clogged bottom tubes is no big deal, a bunch of them is a big deal.

To clear clogged tubes, you have to “Rod” them, run a steel rod thru the tube from the fire side, and out thru to the smoke box ( kinda like a Roto-rooter). Useless to do, if the front is clogged up by a big pile of cinders. Shovel out the smoke box cinders, so the tubes are clear, and can be productive.

Pete Lassen said:

See this is why I like diesels, none of this smokebox ashpit stuff to learn, fuel in smoke out the stack, pull freight. Simple , like my mind.

Ok enuff snarkyness, Jon , I keep looking at my Beer and BBQ thinking this thing is goint to be huge , but when I place a boxcar beside it, it looks small. Looks like you came up with a good revised plan that is still the same , I like the idea of being able to back it out the back too, seems like I seen one on a layout with a back door, just incase a longer loco needs work , it can go in with part sticking out the back side.

In a recent train mag, there was a first person account of cleaning out the fan room at the front of a dismal, poor guy had to do it with a giant fan whirling over head. It sounded just as dirty and he had to stay hunched over.

It’s a dirty world out there, let’s be careful.

John

Thanks Dave all makes sense

John Passaro said:

John Caughey said:

Use your spare door on the other end and make it a drive through.

Pull it out back to clean out the smoke box.

John

J.C., I think that’s just brilliant! Never would have thought of that.

Devon, I think it’s worth extending the track, for sure.

When I say I never would have thought of that, I’m not kidding: sheepishly admitting my pathetic locomotive ignorance, I didn’t know what a smokebox is, didn’t know why it would have ash, and didn’t know it had to be emptied. But…now…thanks to internet, now that I know what it is, I can see where it gives me excellent visual story-telling possibilities.

Methinks it’s a matter of priorities; you opted to be normal and I followed the life of an artist, lived and worked in Laguna Beach making jewelry… wait a sec, you paint! Ah er um oh yeah, youse gots family, while I be the Great Uncle!

I scoured train mags and learned more and more. Re; smoke boxes; as locos grew so did knowledge of drafting … the cylinders exhaust through it and creates draft in the firebox which helps the fire make steam. Fireboxes can get extensions to improve the circulation. There are baffles and a petticoat to control the ash and cinders… ‘A’ is where the exhaust steam enters at the bottom.

From my files;

Happy Rails

John

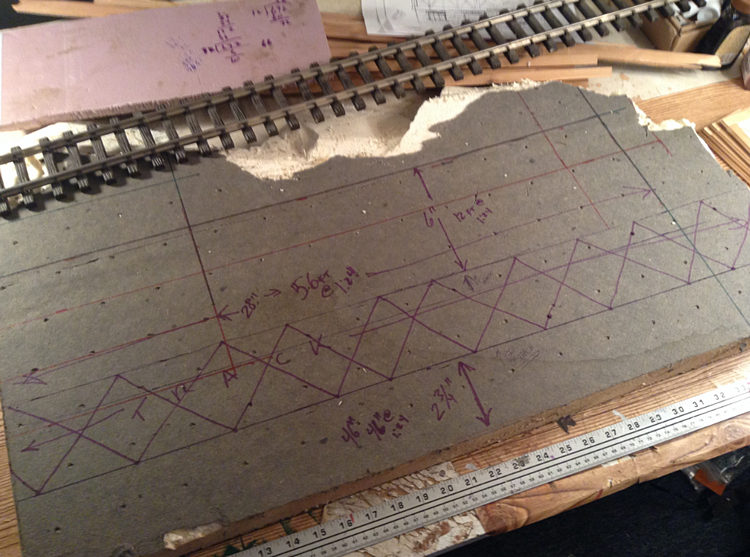

This year I’m into planning and getting things right the first time. That’s what I’m telling myself to justify my glacial progress, to borrow a phrase from Maynard. I’ve been following along all the builds (maybe more than time permits considering how much I’ve gotten accomplished !) and everyone’s ideas are getting carried out very nicely indeed. It’s fascinating to see the different ways of taking a project from an idea to a real build.

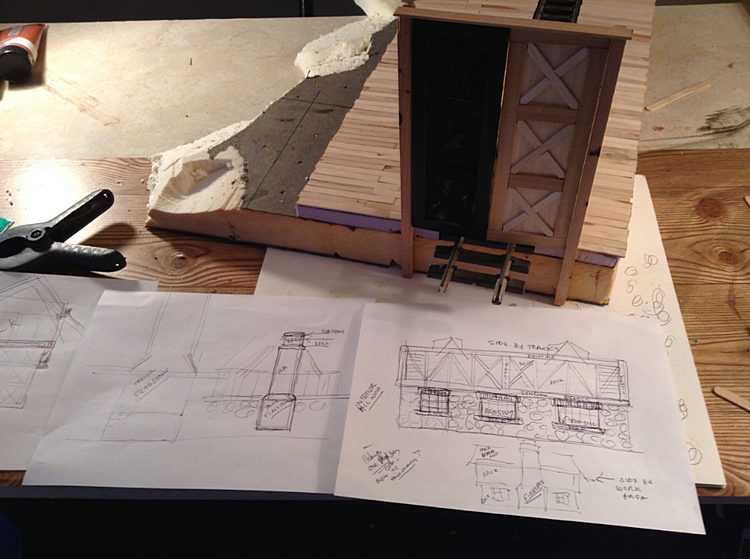

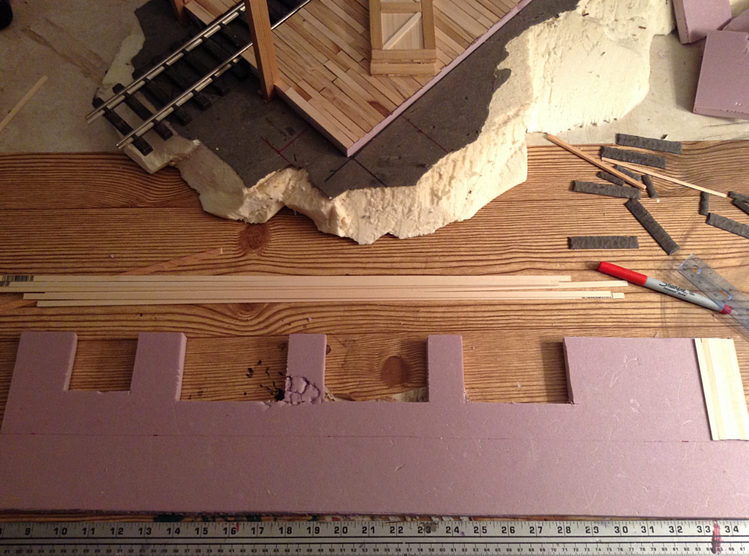

Having built the doors for my engine house, I spent a lot of time getting the proportions of the floor right, getting the proper height to meet the tracks so the boys aren’t tripping over the tracks, and then tediously laying the floor over a insulation base stick by stick and making the framework for the doors.

You can see more thought being put into the design…and you may ask why the door is black? Well, I’m glad you asked. It’s black because I tipped over a bottle of black India ink on the work table and it soaked the wood. Great.

So then I started laying out Dave’s stone for the fireplace, which I think I have enough to make a decent fireplace. I’m not happy with the design just yet, but it’s getting there.

And then finally, it’s about time, I started laying out and building one of the walls, complete with window openings.

I am not going the sintra route. I took your advice and got a scrap from a sign maker and tried to work with it. No way. Not now. I know a lot of guys here are getting great results, but I’m sticking to insulation material for ease of use since my structures are more or less protected from the elements. I’ll just hve to get better at carving insulation if I’m not satisfied with the results.

The interior of the walls will be wooden, nice warm wood walls over the interior rockface. The last picture shows the chapel that I am imitating in terms of the rock walls and the window sills…Dave’s material should work perfectly for the sills if I do a good job of it.

Are you done …Holy Pink embellishments … yet?(http://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-wink.gif)

John

Coming along nicely, John. I love your calculator there on the foam. Looks like some of my scribbling.

John you mention the tripping factor. Would it make sense to fill in between the rails with wood so that there would only be a minimal gap for tripping. .

It is looking great. And the careful planning will pay off.

Devon, I thought about that. I know John Allen’s engine house track is filled in, but, no disrespect intended, I am so over John Allen it isn’t funny. I’ve seen a couple of models where the track is ballasted, see below, and a real life house that is ballasted but it’s a preservation place and I can’t find the picture I was using. The third picture below however shows a real railroad actually changing out the ballast in its engine repair house. That’s why I wanted ballast (well, truth is, I like the look of ballast really) because you can change out the ballast when the locomotive oil drippings get to be too much.

Maybe Dave Taylor can correct me but I thought I saw a picture of the Silverton house where the track was ballasted.

But you have a good point and I think I’ll fill in the track partially in a couple of spots to give the boys a place to cross safely.

Thanks. Suggestions make me think!

In the Silverton Northern engine house, ( facing into the front) the Left track is covered for the first few feet with wood between the rails and outside of the rails, nearly touching, and then the pit starts, beyond the pit it is planked right up to the rail, center and outside. On the Right side stall, again a few feet of total planking, and then no planking due to a mini deep pit of 12-14 inches deep, and then planked inside and out side the rail. NO ballast inside the engine house.

On the D&S, Rail high bailast from the turntable to the doors of the round house, inside concrete on the outside of the rails and I believe planked in-between.

AT Chama, in the old roundhouse part, ballast on both tracks except in the pit. In the new engine house, concrete outside the rails, concrete inside the rails at the end of the pits, and steel grating over part of the pit area.

At Antonito, Engine house, North bay concrete outside, open pit, steel grating , and concrete out the back. South bay. Rail top high bailasted track.

I don’t know if this is any help or not, but the car shop at the Wilmington and Western is all dirt floor. In most places, you can’t even see the ties.

It’s ballast up to the doors and all dirt floor inside.

The engine house is all concrete floor. Ballast all the way to the doors then concrete inside.

Well there you have it. It is done which every way people deem best. I like the ballasted center idea. Both visually it would be interesting and I can see the practicality of it. So I say run with your plan. The partial planking idea is also cool forming the pit. I wish I would have done that now on mine and might even cut out a piece and gravel it/

I like those doors you made. How wide are they?

Just a thought: I ran into a problem when I hinged mine, they wouldn’t open 100% so some of the grab bars on my bigger engines hit going in.

On the floor between the rails you could plank an area in front and behind where a typical loco would sit and leave the rest to save yourself work and time.

On the hinge idea. If you haven’t already decided I made barrel type strap hinges last year that were simple and opened the doors 100%.

to mount them a hole is drilled and the round portion is cut and inserted right up to the flat part. It is a typical mounting into masonry.

Ken Brunt said:

I don’t know if this is any help or not, but the car shop at the Wilmington and Western is all dirt floor. In most places, you can’t even see the ties.

It’s ballast up to the doors and all dirt floor inside.

The engine house is all concrete floor. Ballast all the way to the doors then concrete inside.

This is simple to do and I do it in several places on the T&LBRR. Simply use roofing paper, with the attached rock, cut to fit between the rails, and paint it semi-flat black with Krylon. You can even do curves.

Travis Dague said:

John, if you are going to have hinged doors, ( operational) consider using Radio control Aileron hinges. You can get them at the hobby shop. I used them on my last years Fire House build challenge…

Thanks Todd. I want doors that open and close this year, but I don’t know what to do about hinges. I’m really stuck. The aileron ones I saw are too big for what I have…maybe if I could find smaller ones; I need to keep looking around. I’m thinking my first choice is to imitate the wrought iron bars that are on the original, which I can do, but they wouldn’t be functional. Then find hinges.

I’m thinking taking the hinges off of wooden cigar boxes might be a possibility. Problem is, I threw a bunch of boxes out because I got tired of them cluttering up space. NOW guess what? I could use them. Geez. If this will work, I hope I have enough boxes left that survived my neatness attack.

The other possibility I’m thinking about also comes from cigar boxes: some of them drive basically finish nails through the sides into the lid and the lid opens and closes pivoting on these “hinges.” Very nifty. Then my cosmetic hinges don’t need to actually work. I could live with that, too.

Devon Sinsley said:

On the hinge idea. If you haven’t already decided I made barrel type strap hinges last year that were simple and opened the doors 100%.

to mount them a hole is drilled and the round portion is cut and inserted right up to the flat part. It is a typical mounting into masonry.

I like it and that would be perfect and mirror the original doors exactly, but I could never make those, I don’t have the skill to work with metal, and I would need 24 of them anyway. For right now I better stick with cigar boxes for inspiration. You done good though!

If all else fails and I can’t find anything in the allotted time, I lightly glue them in place as open doors and live to fight another day!