Yeah, I think the brass tubing would work for most applications. Not sure my pocket book would stand for the press fit drill bushings from McMaster-Carr. Whew!! That could get expensive quick.

Don’t chuck on the flutes, they are hardened and may break.

For the ore cars make a template in 20 ga. sheet brass, keeping the tubes from wandering puts your fingers at risk

Am following in awe Cliff , fantastic skills ! Its gonna be a real masterpiece .

John Caughey said:

Don’t chuck on the flutes, they are hardened and may break.

For the ore cars make a template in 20 ga. sheet brass, keeping the tubes from wandering puts your fingers at risk

Oh. That’s why that happens…

Good idea! And a laser’ed jig could locate the pilot drills. Then there’d be precision and durability.

mike dorsch said:

Am following in awe Cliff , fantastic skills ! Its gonna be a real masterpiece .

Thanks Mike!!

I sure appreciate the encouragement, and will try hard to live up to your generous words!

mike dorsch said:

Am following in awe Cliff , fantastic skills ! Its gonna be a real masterpiece .

Fantastic indeed - while he takes very good pictures, his models look even better in person.

(Although I do believe that the 17th hole in that jig must be at least 1/8” scale to the right of where it’s supposed to be.(http://largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-foot-in-mouth.gif))

Cliff Jennings said:

John Caughey said:

Don’t chuck on the flutes, they are hardened and may break.

For the ore cars make a template in 20 ga. sheet brass, keeping the tubes from wandering puts your fingers at risk

Oh. That’s why that happens…

Good idea! And a laser’ed jig could locate the pilot drills. Then there’d be precision and durability.

What size pilot drill do you use for a 1/32" hole? (https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-wink.gif)

Dan Hilyer said:

Cliff Jennings said:

John Caughey said:

Don’t chuck on the flutes, they are hardened and may break.

For the ore cars make a template in 20 ga. sheet brass, keeping the tubes from wandering puts your fingers at risk

Oh. That’s why that happens…

Good idea! And a laser’ed jig could locate the pilot drills. Then there’d be precision and durability.

What size pilot drill do you use for a 1/32" hole? (https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-wink.gif)

Touche!

(https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-laughing.gif)

Bruce D. Chandler said:

mike dorsch said:

Am following in awe Cliff , fantastic skills ! Its gonna be a real masterpiece .

Fantastic indeed - while he takes very good pictures, his models look even better in person.

(Although I do believe that the 17th hole in that jig must be at least 1/8” scale to the right of where it’s supposed to be.(http://largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-foot-in-mouth.gif))

Thanks Bruce! You’re being too generous, but thanks bro, means a lot. (https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-laughing.gif)

Jim Rowson said:

Kewl! How long is this? What are the implications of non-compression?

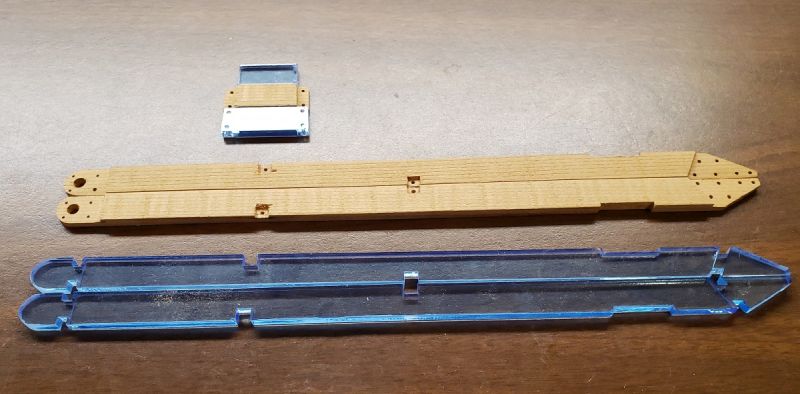

Jim, I’m in a better position to respond to your question now. Here’s the frame, with a Hartland flat on the left and an LGB on the right. The derrick is 1:24, and I’d thought it would seem small. Now I’m concerned it’ll make it around my layout without knocking into something, haha!

===>Cliffy

Not sure how I missed this but here we go again!! …![]()

" Rooster " said:

Not sure how I missed this but here we go again!! …

Yeah…and he always has that one thing off by a scale 1/8” too (and never fixes it!) (http://largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-foot-in-mouth.gif)

Right.(http://largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-embarassed.gif)

Beautiful work, Cliff! (We were hoping to see you at KOPS(http://largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-surprised.gif))

Thanks Bruce, thanks Rooster!

Back to scale… It’s really weird, looking at the derrick frame; seems huge – especially for 1:24!! But I just checked, and yep, it was 36’ long x 10’ wide. So, 18" x 5". But still makes everything else I have seem puny, including my 1:24 (???) Hartland 4-4-0 loco that should look just right with this.

LGB used the good 'ol “rubber scale,” as we all know and love. But for all the other manufacturers, now I’m wondering if and how much rubber they used in their scaling…?

===>Cliffy

Well Hartland omitted a boiler course to shorten the 4-4-0 loco, should have been the diameter of the smoke box and placed behind it. I’m sure they did it to navigate tight curves.

I use bees wax as my lube when drilling metal using micro bits. As it warms, it gets liquid to float the bits out and dosen’t fling itself about. I also resharpen bits on the sides of separating discs, but since that can be dangerous you didn’t see that here.(https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-wink.gif) Always wear goggles or a face shield. I wear Optivisors as mine(https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-wink.gif).

I did the main notching and misc. drilling today, using a few simple templates.

After all that hole drilling, I was sweating it with the notch locations. Really easy to get the notch on the wrong side or end! So I double checked everything before cutting, and all looked fine afterwards. Until a final QC check, where I saw I’d put a pair of notches on the upper side of one big intermediate sill… aaargh! Well, that’s what wood filler’s for. And it’s up against the deck, on the underside. And no one will ever notice (unless they read this thread). (https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-foot-in-mouth.gif)

===>Cliffy

Today was more of the same, with these main beams of the boom taking up about an hour each – even with the templates.

Except for the lower right notches, all the others on the template are to mark side notch boundaries, which are only 1/16" deep.

Fun work, and I didn’t even cut myself once!

Next is all the brass parts…

Thanks for the thanks, brothers! Always means a lot.

Coming along nicely, Cliff. Pause for a minute so I can go refill my drink and get another tub of popcorn … Ok, I’m back. Carry on (http://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-wink.gif)

Now Cliff: if you didn’t cut yourself is it really a model?

just to get it straight…

what are the templates, and what the model pieces??

in other words: will this be a wood-, or a plexi-model?

(just confused)