Truly impressive work

Wow! Very nice work.

Gary Buchanan, FOG said:

I’ve done a few, tedious but doable, mine are all code 332 aluminum so no soldering is needed

You say I have issues ?

Aww come on Rooster, building track work is challenging fun, populating a box cab with rivets is just mind deadening !(https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-wink.gif)

Stan your work looks great, that you are using more to scale rail makes my attempts look toy like !

Devon Sinsley said:

interesting challenge. what are the gauges? 45/32?

Dev, I’ve asked twice more after you, and we still haven’t gotten an answer…

I was at first thinking F standard / narrow, but now guessing G/O. Maybe we should place bets?

(https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-foot-in-mouth.gif)

I thought Stan had answered but he has elsewhere here it is

"The railroad is 3 foot narrow gauge on 45 mm track which is 1:20.32 or Fn3.

F scale Standard Gauge runs on track which is gauge of 70.69 mm. The dual gauge turnout supports both track gauges ."

Stanley Ames said:

I model in F Scale so the gauges are 70.6mm for standard gauge and 45mm for 3 ft narrow gauge.

Here’s the answer as to what gauge Stan uses. Page 1.

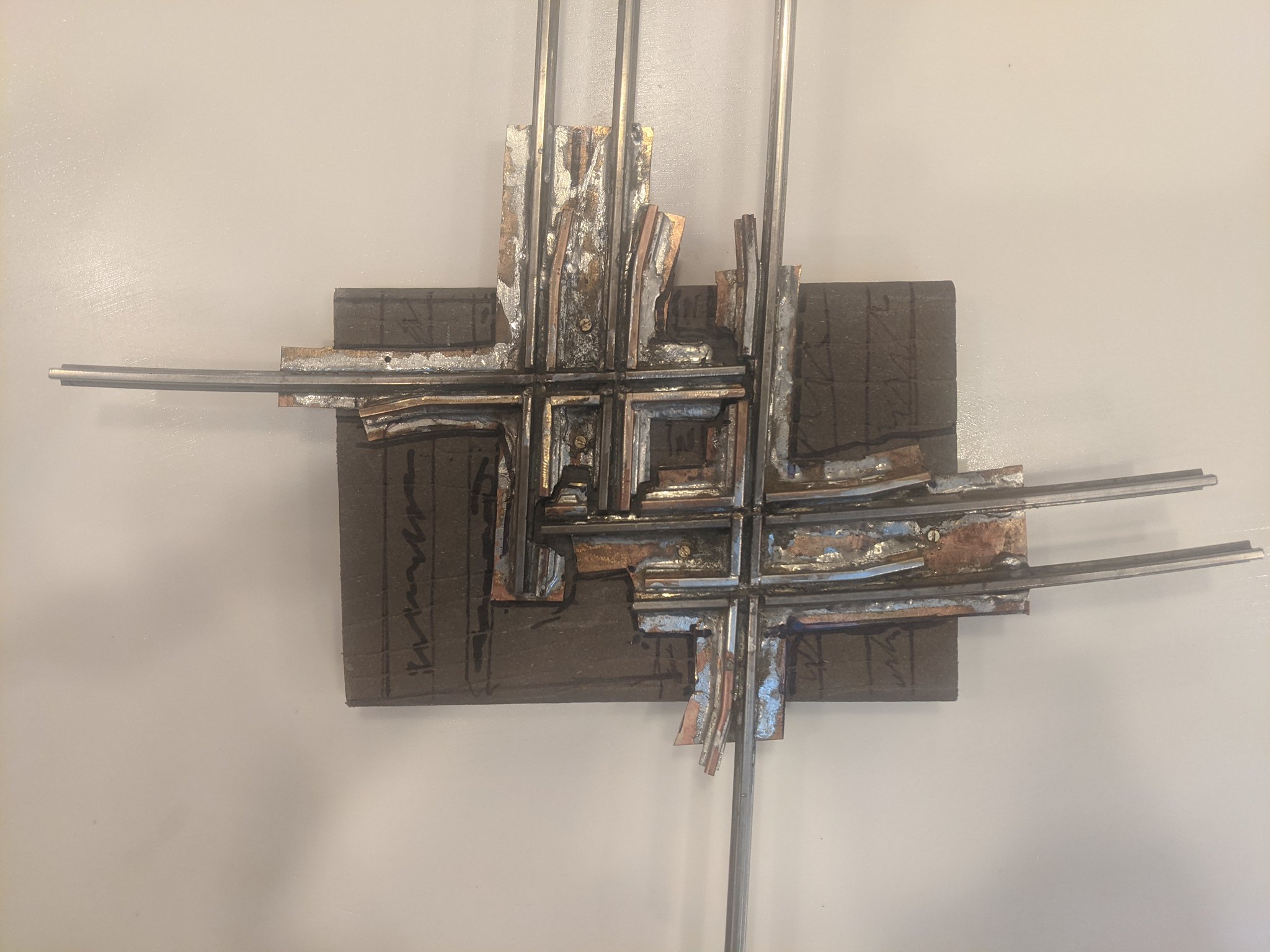

Since Dual Gauge has been a topic lately I thought I would provide an update.

I continue to develop the standard gauge interchage for the SJR&P.

The dual gauge area will eventually have a wye, several industries, and an entry to the yard.

Currently I have 3 of the 8 dual gauge turnouts installed and am turning my attention to the crossing that will be part of the wye and leads into one of the industries.

First up is laying out the track pieces to plan on which frogs will be powered and which need to be insolutated.

(https://photos.app.goo.gl/brLNjFdEb9fG3D527)

Next is to build the two powered frogs. The individual rail pieces are cut and screwed to a brass plate Once the gaurd rails are added these will be soldered to the plate and then screwed on to the tie base.

(https://photos.app.goo.gl/RUGoC939f6UPD6fi9)

Stan

Since we are track powered only two of the 4 crosssings can be metal, the other two will be formed using epoxy once al the parts are in place.

I use a jig to hold the pieces in place during soldering

Next I place the two powered crossings on the tie base. I start with a solid piece and then will cut ties into it before staining it black

Once this step is done I will go about making the other three track sections to complete the crossings and mount everyting on the base.

Stan

Finially got the diamond completed. Alas will have to wait till a thaw before I can instal it.

a couple additional photos of the build log.

First I had to build the extra pieces and install everything

Since this is a track powered layout several of the frogs must be insolated. To d0 this the frogs are build up using epoxy.

And finially the frogs are cut out and the brass plates painted. Once it goes outside the brass gaurd rails will tarnish and the ballast will hide some of the brass plates and it will look better

My next dual gauge work will be to build a draw. A draw moves the narrow gauge from one side to the other and is necessary inside a wye.

Stan