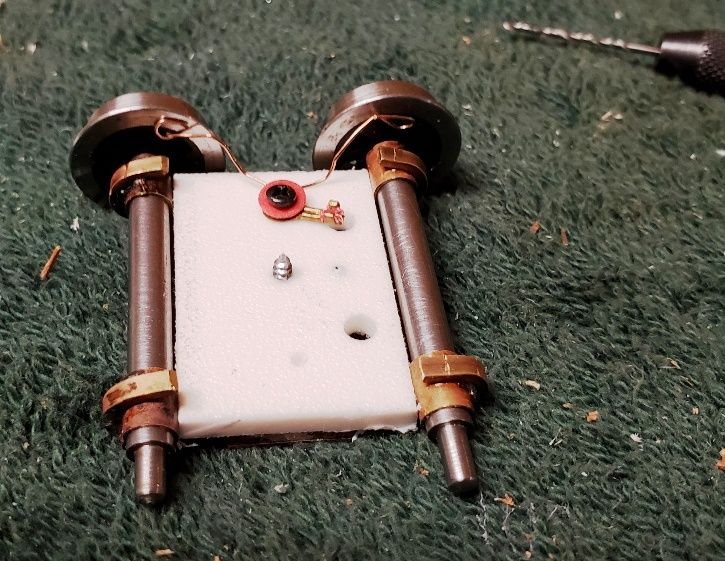

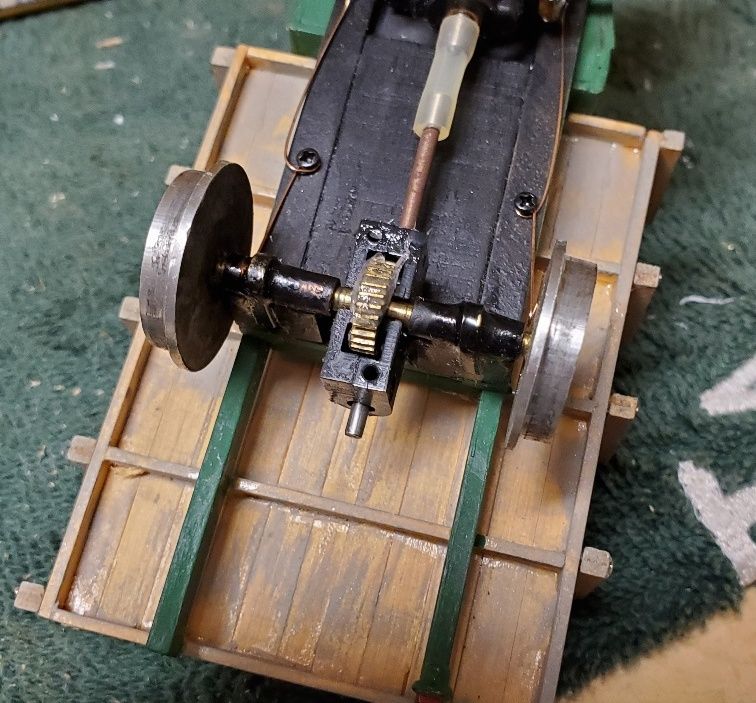

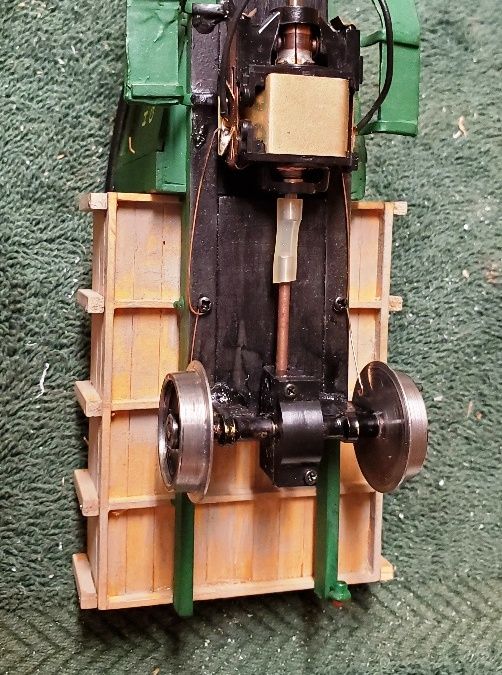

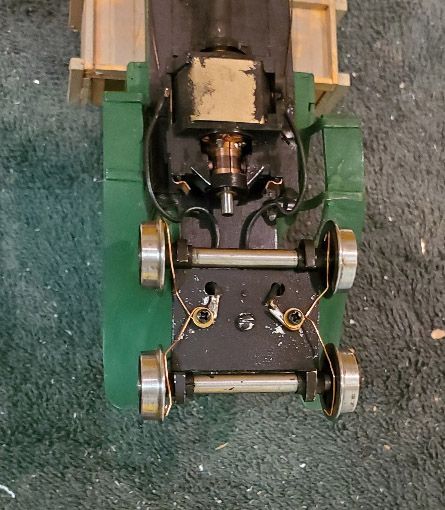

This turned up yesterday, acquired from an estate in Canada. It’s a Northeast Narrow Gauge “kit” and the owner did a beautiful job putting it together. It has one major design problem, the track pickups are a huge brass slider between the front wheels, which is all very well but won’t go over a dead frog. New pickups on the wheels are scheduled - I have some phosphor bronze wire (sold for trolley overhead) which does an excellent job.

The reason for bringing it to your attention is those horrible front wheels. They are about 1/2" across the treads and over 3/4" inch over the flanges. I can find 7/8" wheels but I haven’t found anything smaller.

Anyone expert in Lionel or other Gauge-0 wheels? Be nice to find some almost scale 3/4" spoked wheels. I can always find a longer axle.