While i was milling wood for the Challenge work caboose, I went ahead and cut enough to do 3 cars. Next on the bench is a simple 30 foot flatcar. Nothing fancy. I’m going to use it to practice weathering and find something I like before I finish the weathering on the caboose. I’m also 3D printing a few more parts on this car just to see how they look for future builds. So, I guess this is sort of a prototyping car ![]() . Not sure if I’ve shown them before, but while I was working on the archbar side frames for the caboose, I modeled the Andrews side frames. They will be used on the flatcar. Here is the car in its current state.

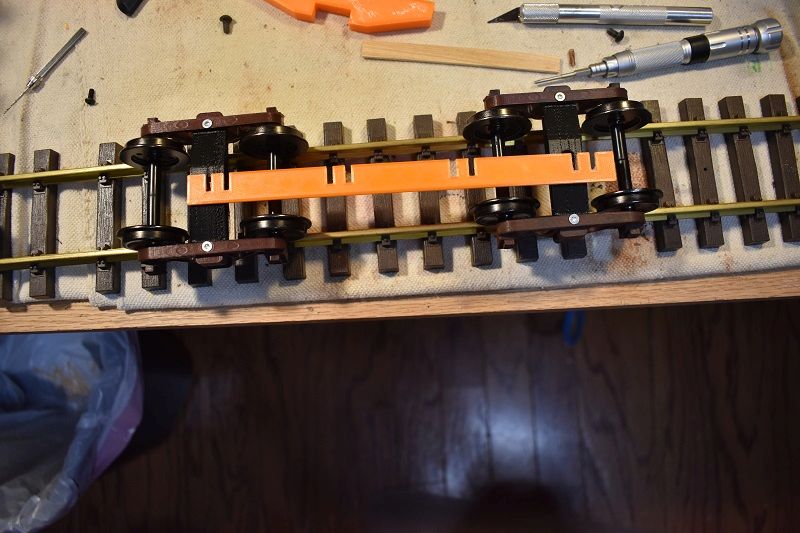

. Not sure if I’ve shown them before, but while I was working on the archbar side frames for the caboose, I modeled the Andrews side frames. They will be used on the flatcar. Here is the car in its current state.

And the Andrews trucks.

Other than the trucks and bolsters, I’ve printed the end beams with integral coupler pockets. I’m printing everything in orange so that when I’m done I can post a photo or two and you’ll be able to see everything that has been printed. I’ll cover it up during the painting and weathering phase.

Notice the holes for the trussrod NBWs. Actually the end beam in the photo is scrap. The holes were a little high. I’ve adjusted them on the beams on the car.

I’m using Kadee 1906 #1 couplers.

Hopefully, I’ll get the flooring on tonight and maybe mount the queen posts. Thanks for following along.