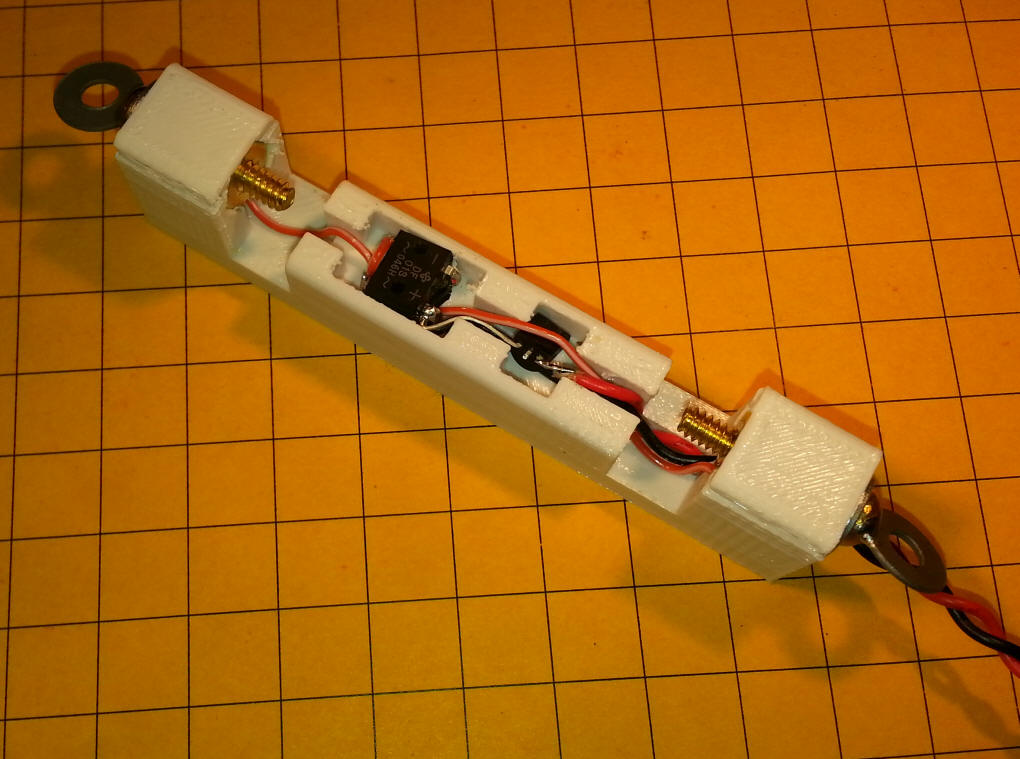

The Pittsburgh Garden Railway Society sets up layouts at a number of community events and train shows each year. We have an assortment of buildings that sit along the track and I like to see lighting inside of them as it adds to the realism of the display. Options for powering the lighting for these buildings include running wires to each building from some central location or operating from batteries. I am not a big fan of either of these methods of getting power to the buildings. Since each building is quite close to the track and the track has power most if not all of the time, I decided to experiment with pickups that would feed power from the track to LEDs that would light the buildings.

Details on how the track pickup & circuitry are on my web page here:

http://trainelectronics.com/Articles/TrackPickupLEDs/

dave