Time to replace a bad dry rotted retaining wall and add a second main line.

Setting peeler post in and drill holes for Rebar.

Addi roofing materiel to help from dry rot. This area gets a lot of watering from our walker sprinkler.

Wall pulled out the original main line to re level the area and set up two main lines.

Had to remover more of the small Mt. and shrubs to make a better run.

Forgot to post why the soldering unit and shrink tubing was showing. I accident with an axle when chopping out roots, I cut some underground control wires…

Had to repair the 8 pr. wires that controls the relay for the upper run that blocks the set up area. Also the Signal for that area and the signals and blocks to the main line at Hillsdale “Y”. I bad… what a mess i made. That took some extra time. to fix. . Woulden’t be so bad except we are all track power here.

Kind of fig. how the two tracks are going to work.

Pulled out the old Switch coming from two tracks to single main. Re-install siding switch on nbr two main.

Starting bend the outer main with the old main relayed. Keeped the 10 R. run on the inside and making the outer run around 11 1/4 R. so far. This is giving a little extra room for long pass cars on the outer run.

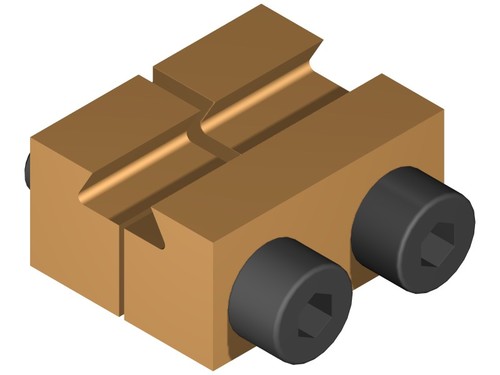

Question… Has anyone done a flex track splice with an offset for Hilman Joiners?

The other tracks I done years ago are, I just cut off even on both rails but, its not a good even curve to get right sometimes.

I’m going to try to slide one of the ties up on one rail for a off set. Put a Hilman on each off set rail. Hope to make maybe see if my Train L rail bender will go thru it for a better curve.

Has anyone tried this??? I’m not having much luck today… so far I missed up and pinched my fingers. ![]() &@#*% LoL

&@#*% LoL

Seams like always something to work on every year…

We see that most of the set up area that is a 100 foot run, boards need to be replaced. Going to try using new re-cyl. plastic deck board that are around16 foot links and see if that will work… Course… that another project after getting this main line along the walk way done.