Anyone who has converted a live steam engine to radio control has bumped in to the question of how much the throttle servo has to turn the throttle shaft in order to make the engine go properly. In general, most engines will move on 10-20 degrees of shaft movement, but on an uphill line with 6 heavy coaches you may feel that 180 degrees will be required.

Some years ago I converted my Accucraft C-16 and managed to get about 135 degrees of movement (see below.) My Accu EBT #12 had only 90 degrees as I didn’t try anything special, though I recall Kevin saying he wanted 180 to be able to give it a big burst of steam when needed. Most live steamers only seem to need about 90 degrees max to function, though you hear that more might be better. With Jason selling longer tapered fine control throttle shafts, you will definitely need to think about the shaft rotation.

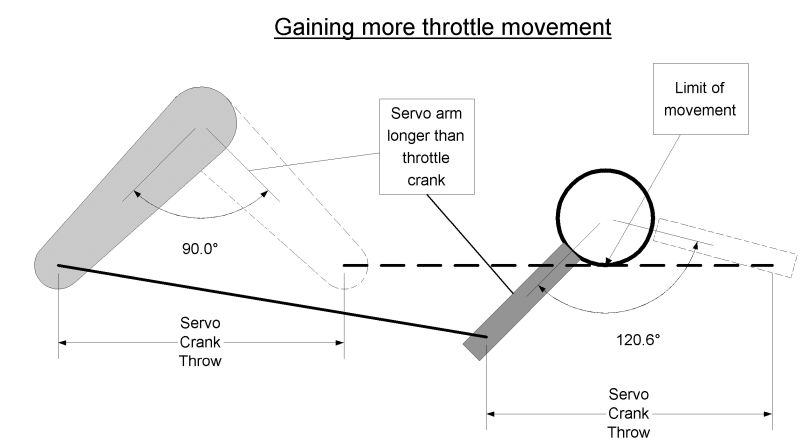

My C-16 originally had a regular servo and a long servo arm connected by a wire to the throttle shaft crank, which was shorter than the servo arm. Simple geometry will show that a long arm moving a shorter one will make the short one move further. I think I got about 110 degrees, but it is tough to go further as you run in to the mechanical problems of such arms.

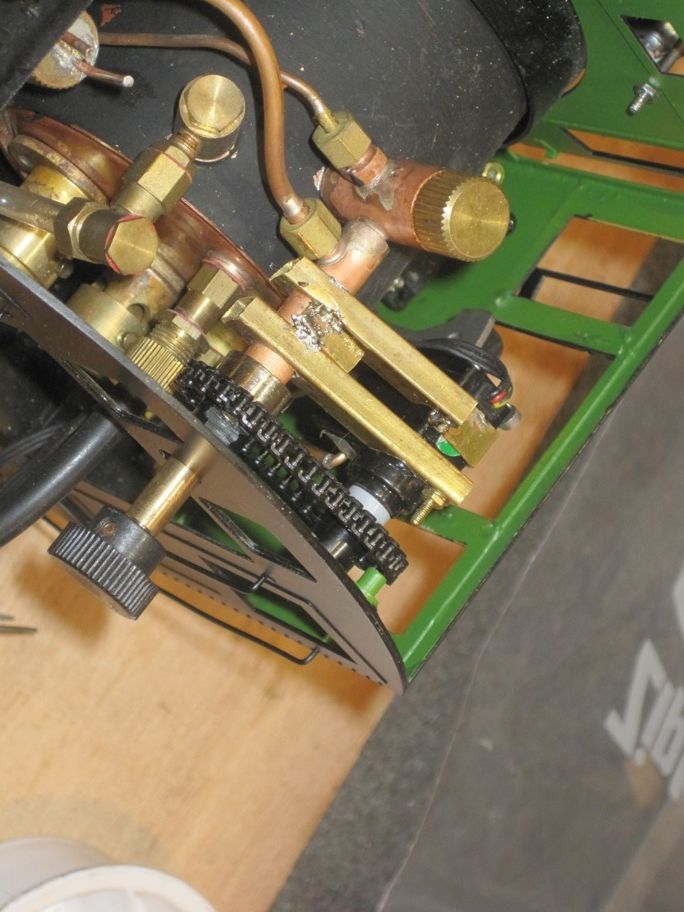

My C-19, on the other hand, had chain drive (1/8" nylon from Servocity.) In theory, this allows you to alter the ratio of turns between the servo and the throttle shaft and thus move the shaft as much as you want. A 12 tooth sprocket on the throttle being turned by an 18 tooth on the servo will give you a 1.5 times advantage (i.e. if the servo turns 90 deg, the throttle turns 135.)

There are 2 problems - the torque needed is directly proportional to the ratio of the connection (i.e. in the example above, you need 50% more torque than a 1:1 connection,) - and there is a size limit to what can be fitted inside a (model) loco cab. (Followng pic is my EBT#12, but the C-19 was similar.)

I found a 180 degree servo, and replaced the servo in the C-19. As it turned out, my TX (Deltang TX20) was only sending a 75% move command so my 180 degree servo was only moving 135 degrees! However, it was more than adequate. I did research changing the TX to a 100% throttle throw, but it got too complicated and the engine was performing fine, so it was left in that state.

Recently I added a throttle servo to my K4 (another thread, when I get time) and pondered the same issue. I found a bunch of servos on aliexpress that promised 180, 270 or 360 degrees of rotation, for the robot guys I believe. However, when they arrived I could see no advantage - most just turned 90 degrees on my test receiver. One did almost 180 degrees - a Futaba S3003 which was supposed to do 270 (as ordered.) More research was needed.

It turns (!) out that the pulse sent to the servo (from the RX, under command of the TX) needs to be extended to make it turn more. The throw on the servos can sometimes be adjusted at the TX - the Spektrum Dx6i will allow you to request a 150% throw on any channels. At the moment I have not found a TX that can ask for 200%. Most of the robotic guys seem to be using microprocessors and generating servo pulses in software that are as long as they like.

More to come as my musings and research continue. . .