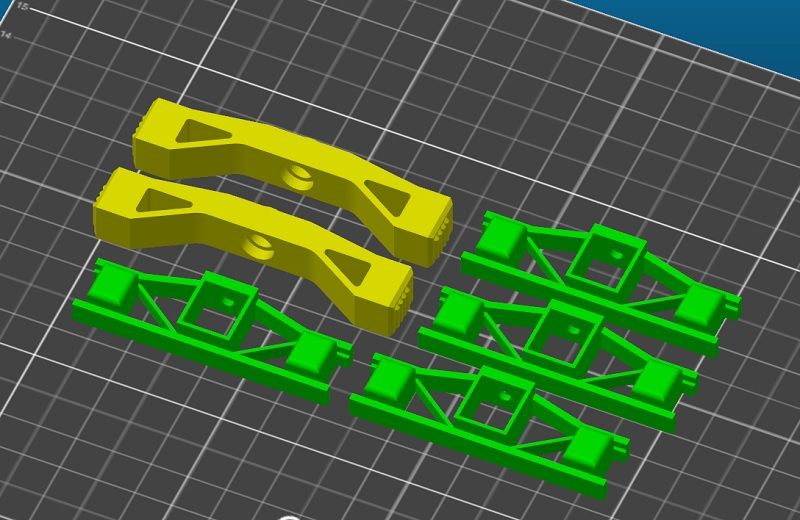

Over the last few weeks I’ve been toying with the idea of making my own archbar trucks. So I sat down at the puter, fired up Fusion 360 and started drawing. After several iterations, I’ve come up with a prototype. They are printed in 3 parts and then put together with the wheel sets to make a complete truck.

The bolster is inserted in the pocket of the side frames and then it is screwed in at the top. Here is the first print.

I’ve since added the spring detail to the ends of the bolster. Not sure how it will turn out but it is on the printer now.

You can just see the scalloping on the ends of the bolster that I hope will resemble a spring. I will continue to add detail as I fine tune the design. There will be a model with bearings. I’ve ordered some 3x6x2 and 3x10x4 bearings and once they arrive where I can get the exact measurements, I will modify the design to accept the them. Don’t pay any attention to the colors. Since these are prototypes and don’t take much filament, I am just using up whatever small rolls I have lying around. I am using PLA for the prototypes but will use PETG for the production models. Let me know if you see any issues or details that I need to add. When I am comfortable with a production model, I will be glad to share the STL file with any of you that would like them.