As the title mentions, the plastic boss that sticks out on the bottom of a car that the truck mounts to. What’s the best way to fix it? I had one crack in half on the bottom of a Bachmann tender.

I have drilled them out and used a plastic dowel before.

I fixed one by putting tubing over the existing pin, and then sanding it down to size.

https://largescalecentral.com/forums/topic/24272/worn-out-lgb-boxcar

But since yours cracked, replacing it with a plastic pin like Travis said, is probably your best option.

Round computer mother board standoffs are great. I have found some large ones in both plastic and metal. These are already taped for screws!!

The plastic wheel sets, offer a bit of help…take one apart, by removing the metal rod, then use the plastic rod part of the half wheel set as a replacement part. Just drill out the broken pin, and insert the replacement pin, after cutting it to size. Since, in most cases, the parts are “Polystyrene”, you can “Weld” the pin in place with lacquer thinner, if you have used the correct sized drill, to give a snug fit. Just proves that plastic wheel sets can have an afterlife use…!!!

I’ve glued a tube, brass or plastic, very thin walled, over the cracked mount. Then glued very small wooden slivers in the cracked hole. Sand them off level after they have dried. Then drill a small hole in the center. Gently thread your screw in to cut new threads in the repaired hole. You will prolly have to ream the truck mounting hole to fit over your new mount. Easy Peasy fix.

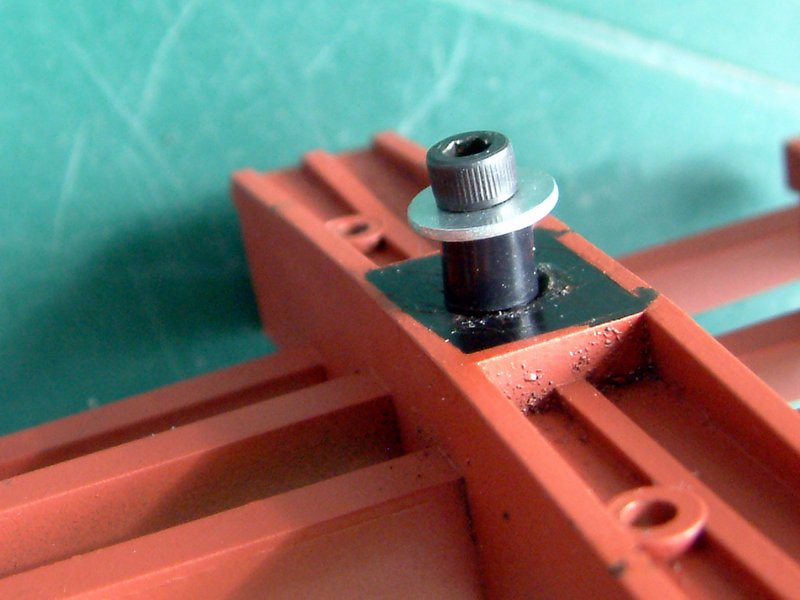

Lots of good ideas here, any one of them will work for you. This is how I fixed the same problem with a T-Nut, machine screw and washer on an Aristo Classic car. Details are in this thread.

Fred Mills. said:

The plastic wheel sets, offer a bit of help…take one apart, by removing the metal rod, then use the plastic rod part of the half wheel set as a replacement part. Just drill out the broken pin, and insert the replacement pin, after cutting it to size. Since, in most cases, the parts are “Polystyrene”, you can “Weld” the pin in place with lacquer thinner, if you have used the correct sized drill, to give a snug fit. Just proves that plastic wheel sets can have an afterlife use…!!!

Interesting and resourceful solution. I will have to keep that in the tool box for future reference.

Thanks Gents for the tips!(https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-laughing.gif) I found some superglue, clamped it with a clothespin, and redrilled the hole, but I like the use of the t-bolt, that’s a great idea!