Canadian National SD60f Build

This thread will follow the construction of an SD60f. I will make it as detailed as possible. It will be a slow project, so if you follow it, you will have to be patient.

This build will require an Aristocraft SD45, 2 pieces of aluminum angles 1/16” x 3/4” x 25 1/2”, 3 USA trains SD70 roof fans, and lots of styrene.

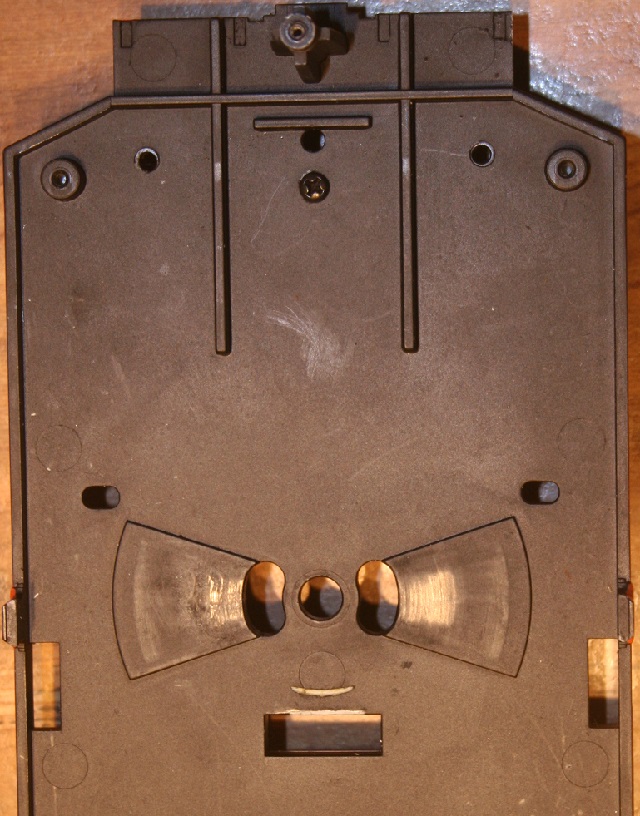

You will need the SD45 trucks, electrical components, end plates/steps, fuel tank and air reservoirs.

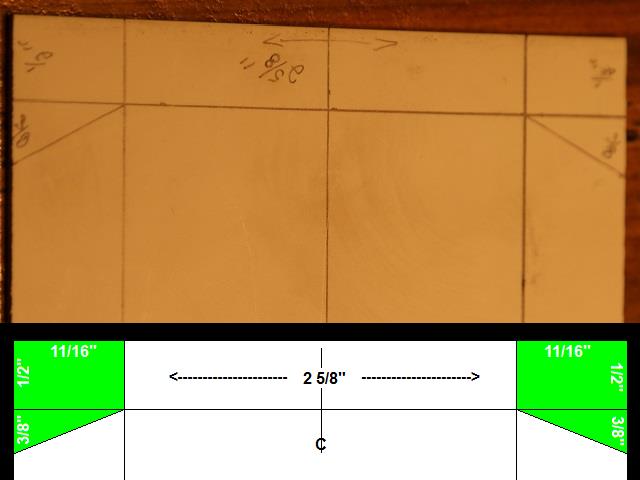

First thing you are going to need is a 27 1/2" x 4" x .125" styrene base.

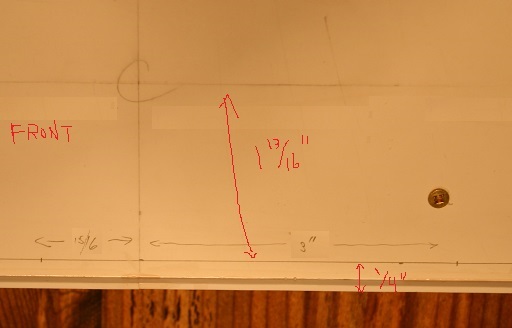

Both ends will need to be cut as shown below. Keep the pieces you cut out as we’ll be using them later.

Now mark your top side, and mount the two aluminum angles. Mount them a 1/2" from the sides and 1" from the ends. I used 6 screws on each one evenly spaced out and it should give you a fairly sturdy base to work with. You can also mark the front and rear to avoid confusion later.

Important - Mark your base center lines on both sides for length and width.