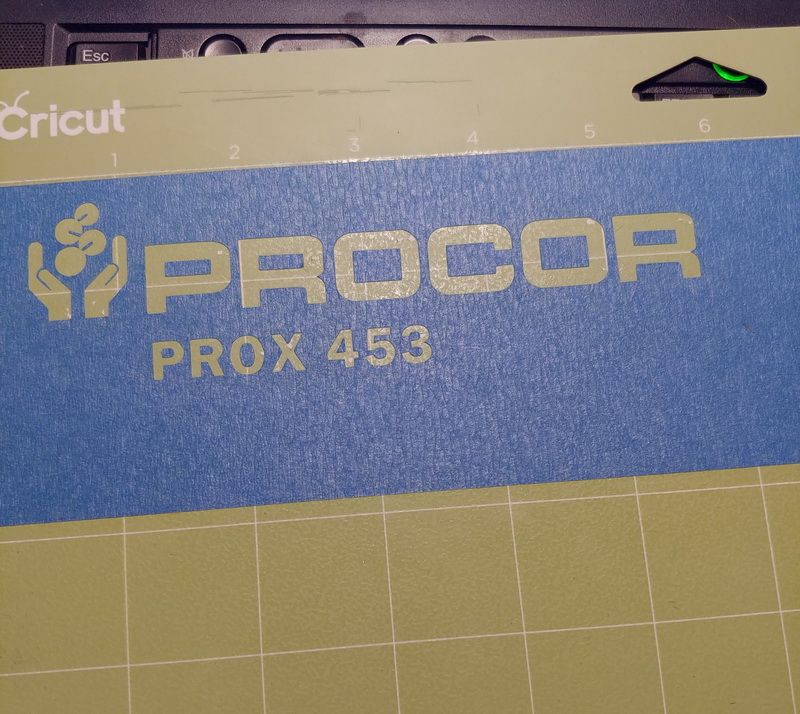

That’s some amazing vinyl cutter work, Cliff and Dan!

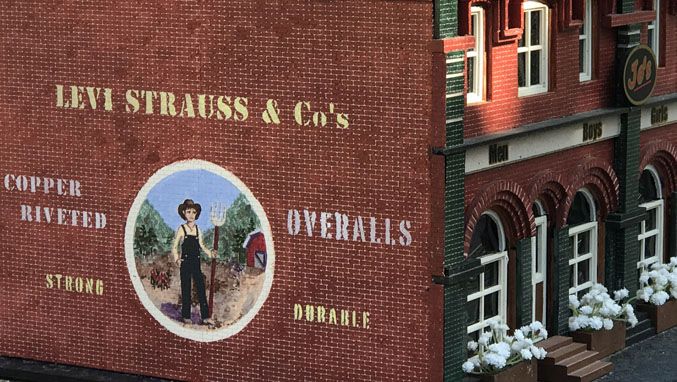

I have the other brand of vinyl cutter, a Silhouette. Very happy with it; have used it mostly for building signage. I use only Oracal 651 vinyl topped with clear UV. Here are a few examples, followed by a couple examples showing the limitations.

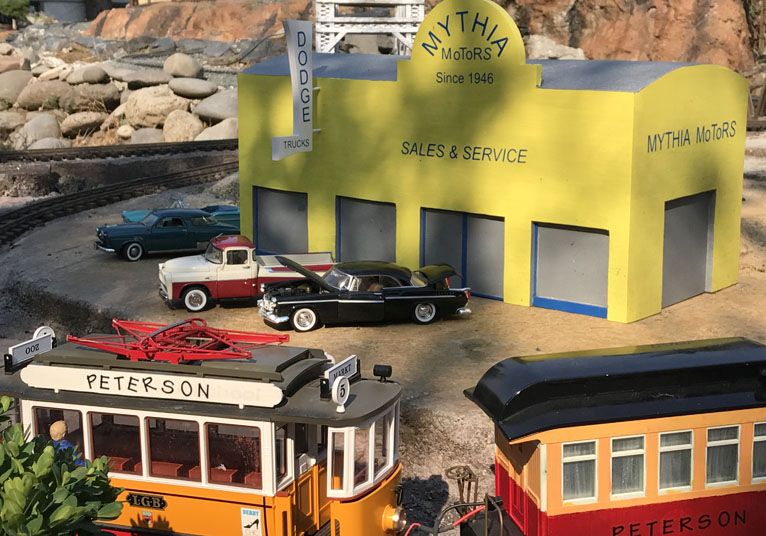

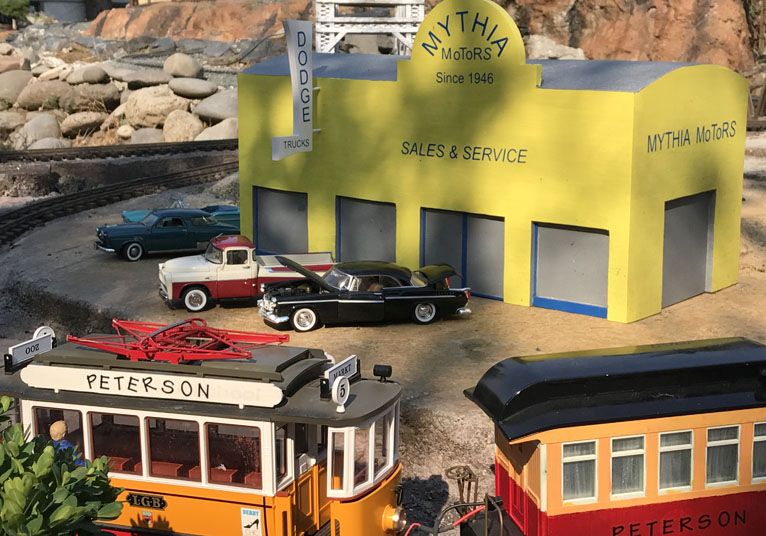

All of the signage on the buildings shown here are done with the vinyl cutter. Although this is indoors at our Thanksgiving show, these buildings have been outside spring thru fall for several years without any issues.

Signage on the building here is vinyl; trolley signage isn’t.

Limitations

-

While my vinyl cutter will cut fine detail with impressive accuracy, I don’t do lettering smaller than about 1/2" high. I’m limited by my ability to weed (remove excess vinyl) and transfer the vinyl to my building. So I wouldn’t try to use it for rolling stock reporting marks.

-

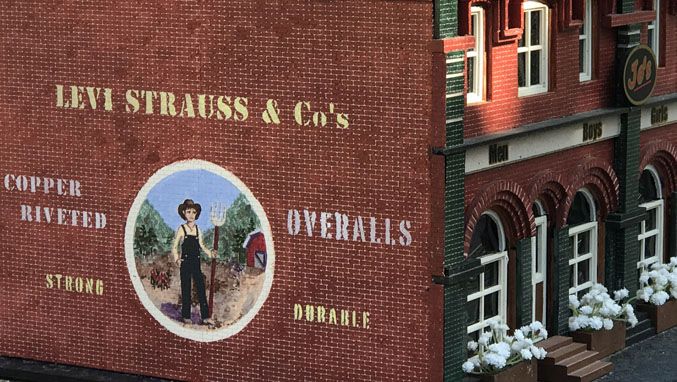

It’s best to adhere the vinyl to a smooth surface, such as ABS sheet. For textured surfaces, I use the vinyl cutter with cardstock and a stencil font as on the building shown here (painting by Mrs. Neals).

- For some reason Oracal 651 does not permanently adhere to styrene. Here you can see the vinyl starting to peel off after just one season in the sun. This has never happened with ABS.

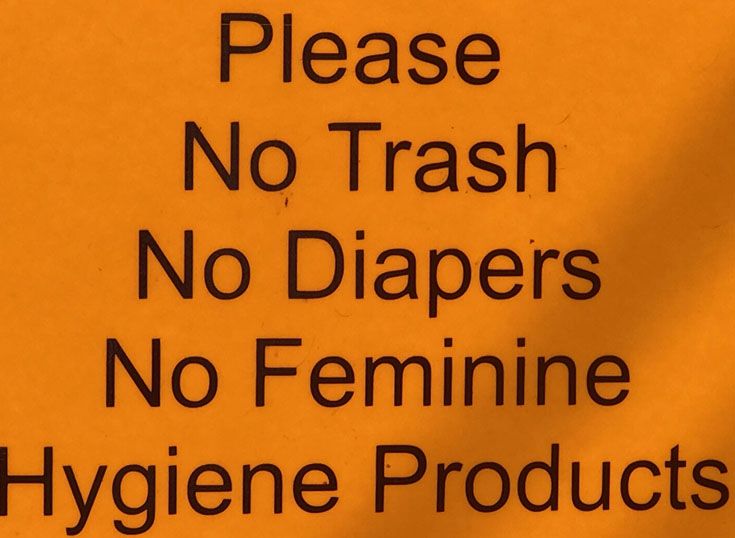

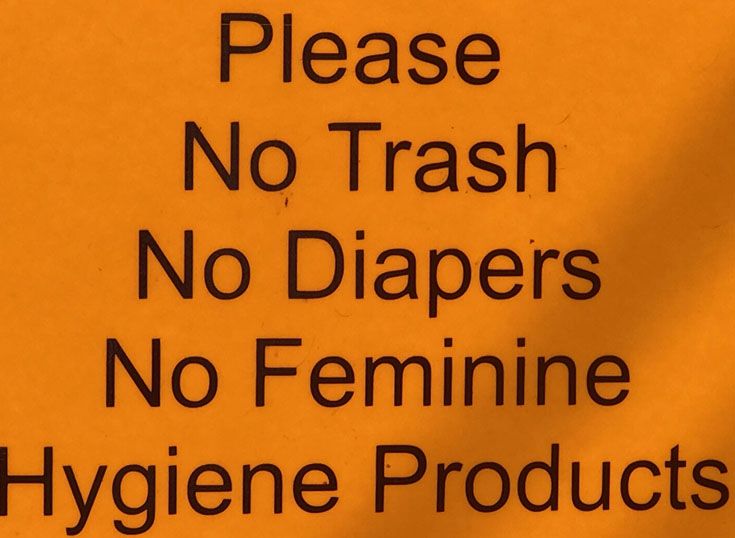

Once you have a vinyl cutter, you’ll find 1:1 scale uses for it as well.