OK answers to some suggestions and more description

-

Korn could you please shed some more light on this statement “now comes the interesting part. for the trestles to stand straight, when everything is finished, they have to be fixed a 3.5° inclinated to the beams.” is this because the bridge is on a grade?

-

Bob and David I thought I may have been a bit misleading when asking about a template my intention is to draw a plan then use that as a template to make a jig so the bents are all the same.

-

Greg the whole thing will be glued and nailed using “Liquid Nails Landscape glue” which is a rubbery adhesive similar to Liquid Nails/Construction adhesive.

This thing will be made out of hardwood decking timber that was ripped out when the deck was replaced it has been thoroughly well seasoned and the deck builder told me it will outlast me.

The timber is so hard that nails cannot be hammered into it unless it is pre drilled I may even go down the screw path yet if I can find the right screws.

Right so I should never caught that virus as I have spent that last 2 days sitting on my deck drinking tea and thinking about the bridges (my wife says I should never be given time to think) as the layout is double track I was originally going to drop the trestle height 100mm below the inside line(the bridge being on the outside line) but know I am thinking a double trestle which, I think, will look impressive, so planning is going to start on that idea.

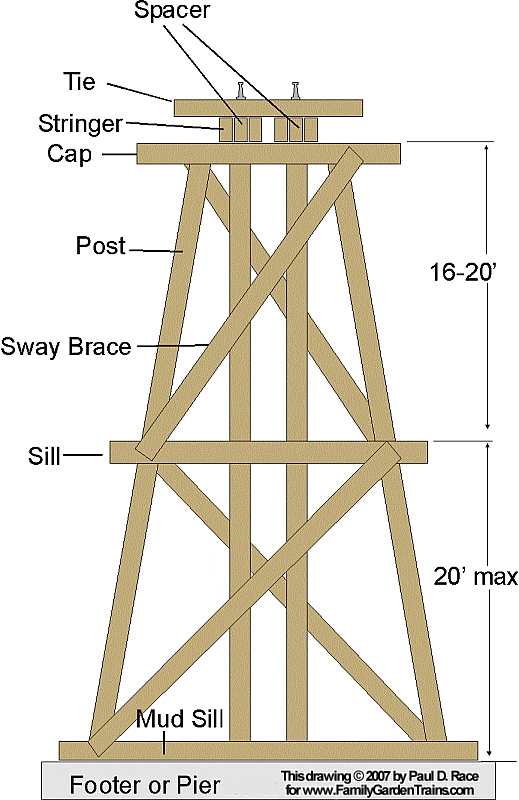

I found this on a HO site so will try to scale it up to see if it is doable.