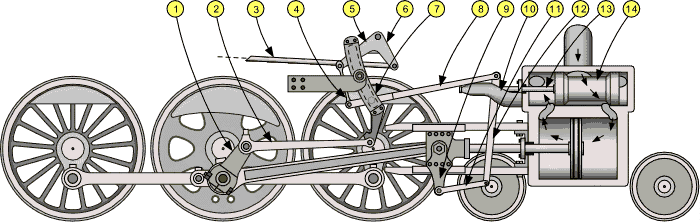

Okay I need some edification on valve gears and how they work. First off I understand the principle of valve gear. In the steam chest it reverses the flow of steam by changing the timing of the incoming steam 180 degrees. So what once was an exhaust stroke now becomes an intake stroke thus changing the stroke of the connecting rod from pulling to pushing on the drivers. I very loosely understand that. This is accomplished with eccentric rods that when set in forward push the valve rod one way thus setting the valve in the steam chest in one position. Then when the rod is moved to its other position it pulls on the valve rod into the opposite position moving the valve in the steam chest to the other position 180 degrees difference in timing.

My first assumption is when the Johnson bar is in the middle position it thus is in neutral by placing the eccentric rods in a manor that puts the steam valve in the chest in the center between the two steam openings this way they are both open which allows equal pressure on both side of the piston and also opens both steam intakes to open and the steam chest is for a lack of better words in both an exhaust and intake position so to just dump the steam out the stack without it driving the piston in either direction. Have i got this assumption right?

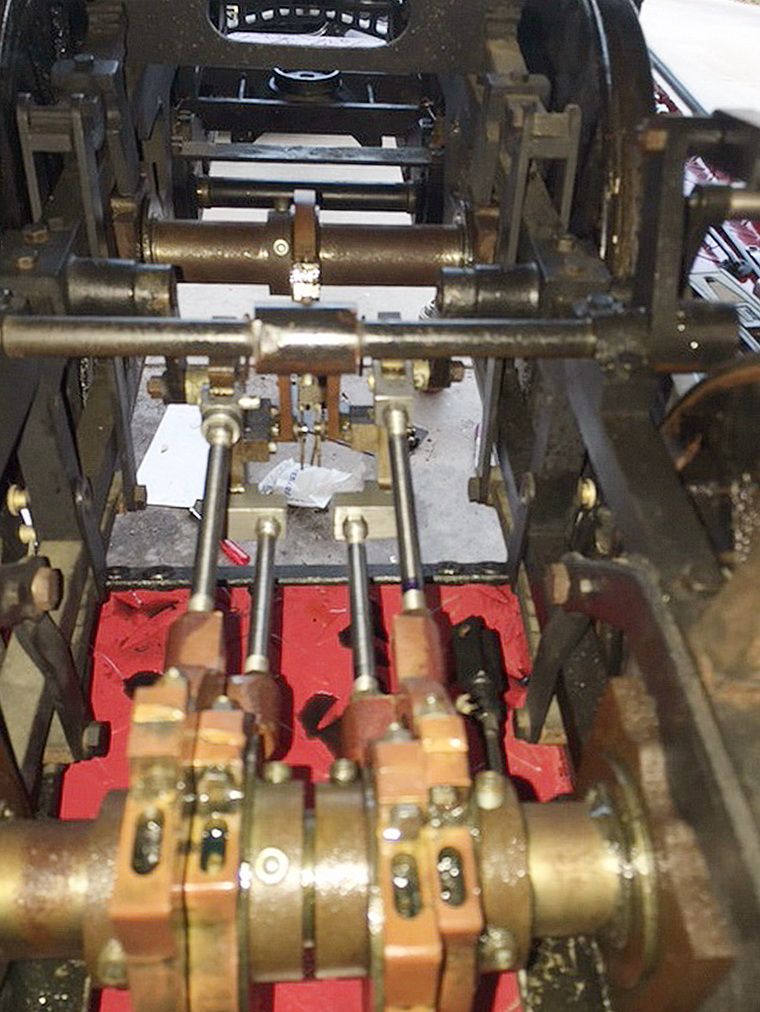

Now if I have all of that right, where I am still a bit fuzzy is how the Johnson bar, eccentric rods, and valve rod work in concert to accomplish all this. I get why eccentric rods are eccentric in shape. As opposed to a crank shaft and connecting rods in a car where the rod is not eccentric but rather uniform in shape and the crank is eccentric. So here is where I am stumped. What causes a perfectly round hole to wobble on a perfectly round shaft. The hole, unless I am mistaken, on the eccentric rod is round and goes on a round shaft. On a car this is true but the shaft itself is offset from center causing the motion. I don’t see how this works on a valve gear. To me nothing is happening that caues the rods to move back and forth.