Just picked up a basically NOS Bachmann Fn3 Murphy Roof box car. It had a rough trip here from FL. Two of the stirrup steps are busted off, both doors and door stops off and one coupler shank shattered ![]() The doors and stops go back on with little effort and I have spare couplers so that is a quick fix, but the steps I’m undecided on.

The doors and stops go back on with little effort and I have spare couplers so that is a quick fix, but the steps I’m undecided on.

I could check with Bachmann to see if they have any, but white metal steps are just going to break again.

I could seek out and buy some brass steps.

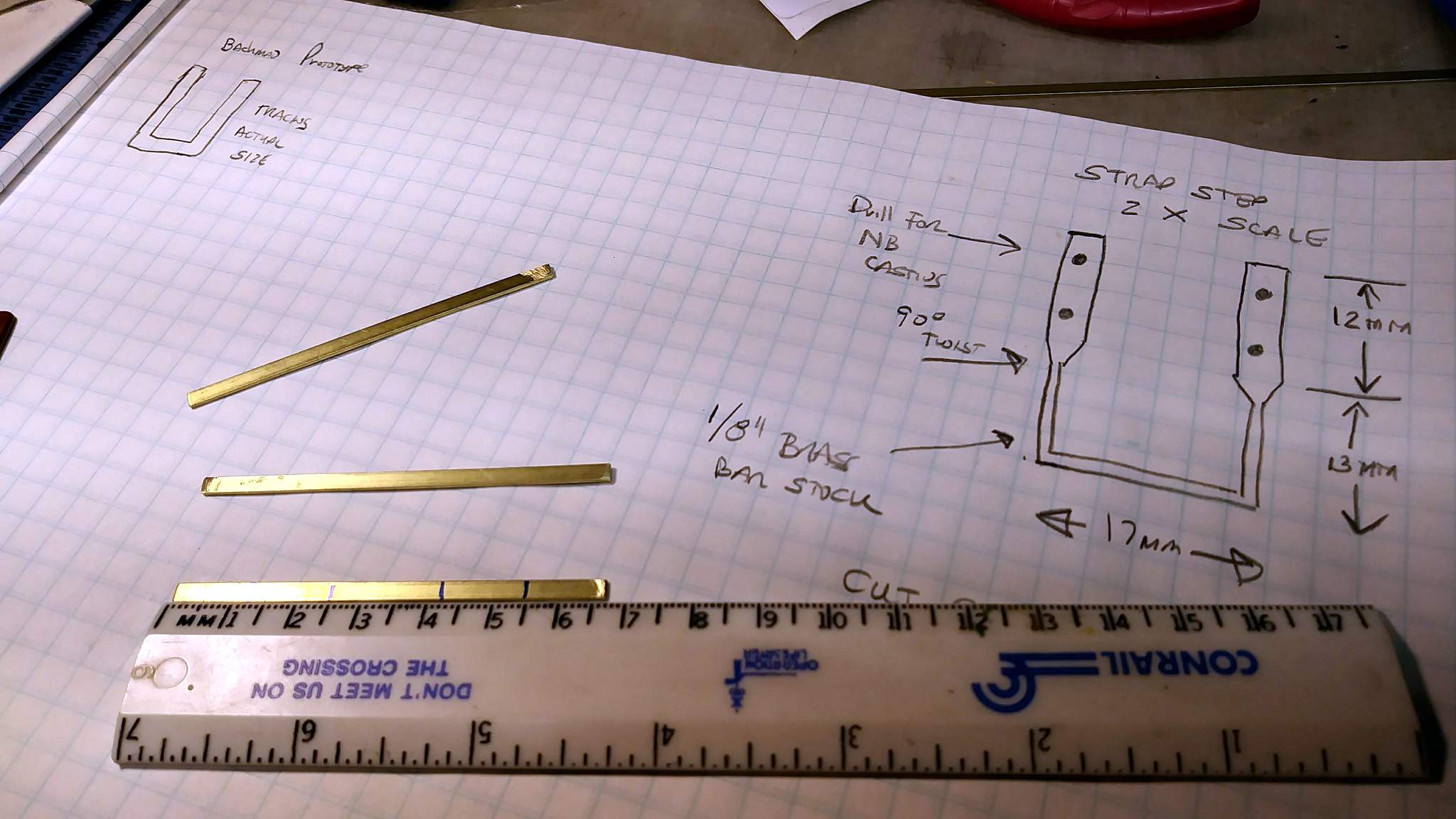

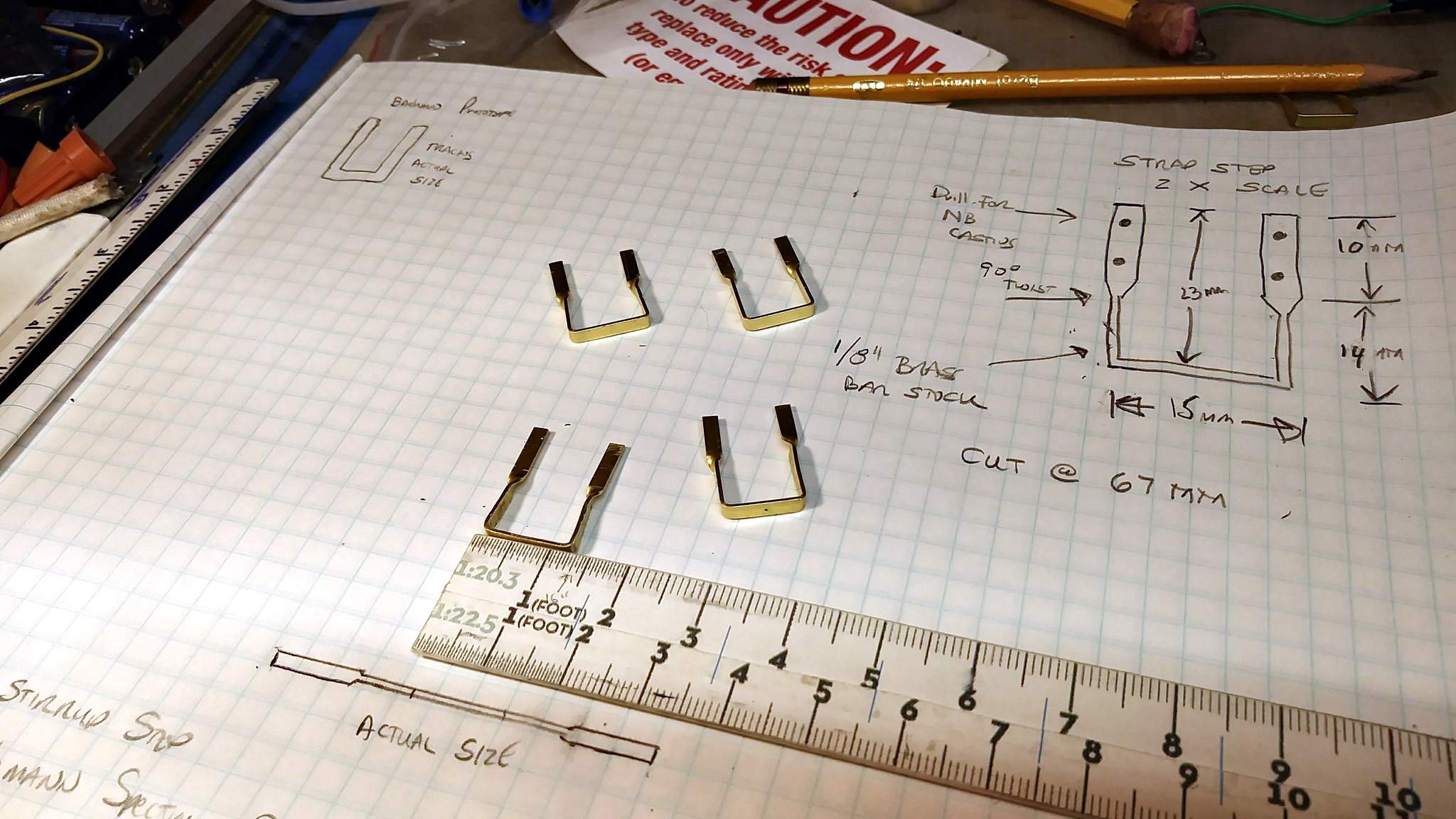

I could buy some strip brass and fabricate a set using Bruce’s technique from many moos ago.

What have you done?

EDIT to fix spelling before I get a PM from Fred.