Dick;

Unless all your cars are of the same make, and have exactly the same underframes, trucks, and wheel sizes; each car can vary in height by anything up to or more than a quarter inch.

To do a dependable and accurate job of body mounting Kadee couplers on rolling stock, it is strongly advisable to treat each car individually, as far as coupler shims are concerned.

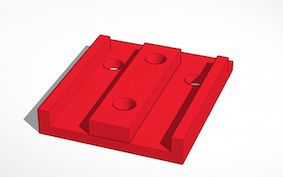

“Printing” out shims is not a bad idea, but, you actually require anywhere up to four thicknesses of shims, not just “One thickness does all”

I use simple shims cut from a few different thicknesses of Styrene flat stock. Depending on the coupler you use, the shims usually only need to be 3/4", or 1" wide, so I cut strips of the styrene to these widths, then cut the strips down to the length needed for the draft gear box required.

I only use the centre hole and end hole on the boxes. seldom are the side holes ever of much, or needed use.

To find the centre hole posithin, I simply position an empty draft gear box on the previously mounted shim(s), and while holding it in place, use a drill bit in a pin vice to make a centering “Dent” in the Styrene. I then remove the box, and place the drill bit in the “Dent”, and eyeball the location of the drill bit to the alignment of the two truck mounting points.

If they line up, then I drill the hole, mount the coupler and box, then drill the rear hole using the positioned box as a guide.

I do NOT use the screws that Kadee is supplying, as I find they are overkill/too large for the job. I use screws of the same size as what they used to supply…but depending on the shims and underframes of the car, I choose frome 3 different lengths, which I keep in stock.

I use a suitable drill bit, so that the screws selftap and do not require tapping, or those pointed selftapping screws…or nuts…

Others may wish to do the job “Their way”, but this simple approach has worked on over 6 hundred cars that I have converted over the years.

I have pretty much standardized on the Kadee 906/1906 couplers. They can be used on just about everything… I have converted USTrains, LGB, Bachmann, Lionel, MDC, Delton, Aristo…and also scratch built cars.

I do not promote the use of offset shank couplers, as they do not look good or are they prototypical…yes there have been some used, but are NOT an AAR standard, or used in general practise.

The only car I have not wanted to converted is the USTrains “Giant” auto carriers…and don’t have any desire to try.

I do not take pictures…not interested in that hobby…

Fred Mills